Joey Collier hey man Merry Christmas to you and your family. I couple of weeks ago when I joined up there was some talk of WS stickers. I am trying to load my helmet lol. Any chance the are still available? Thank you. $?

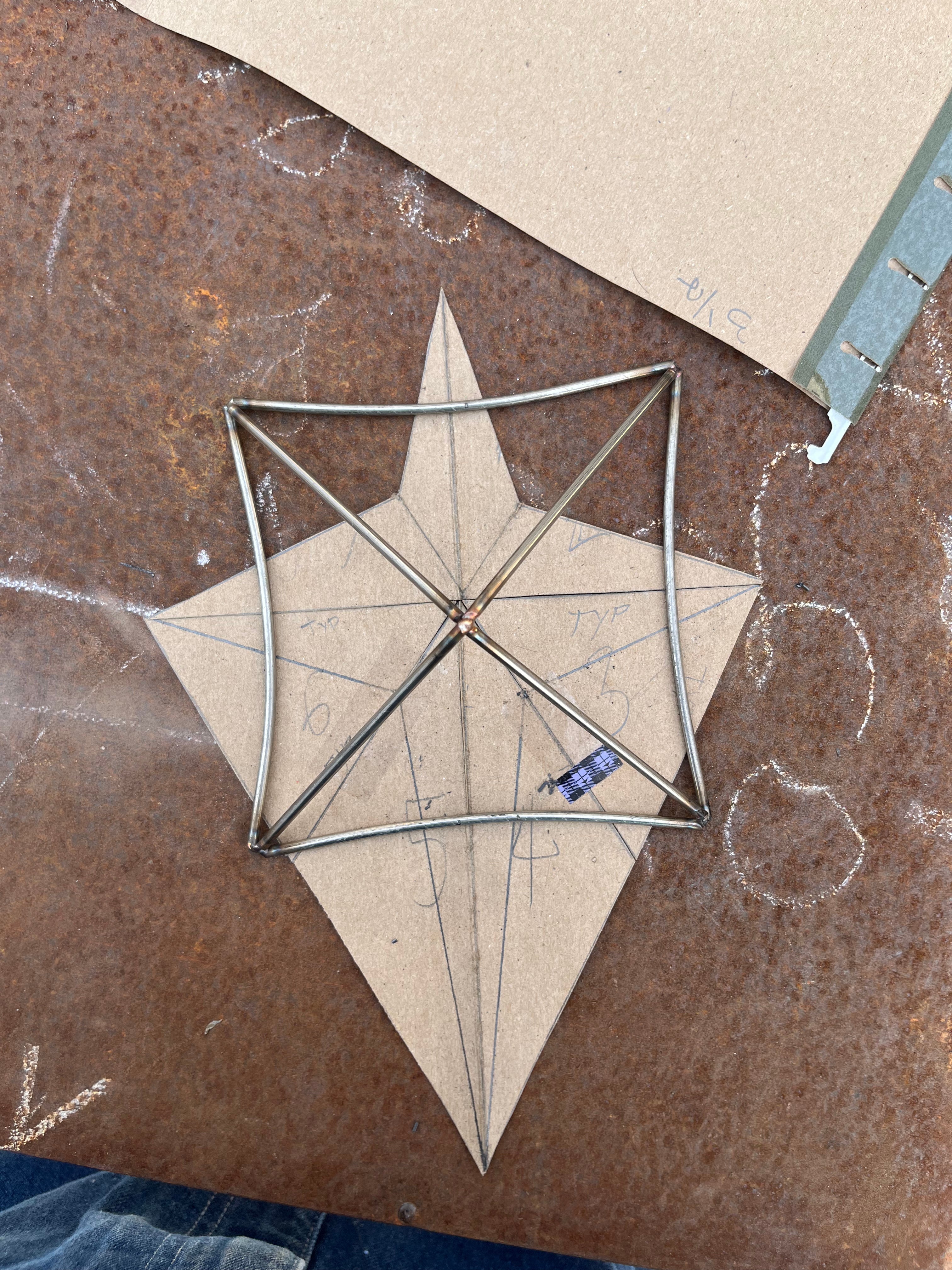

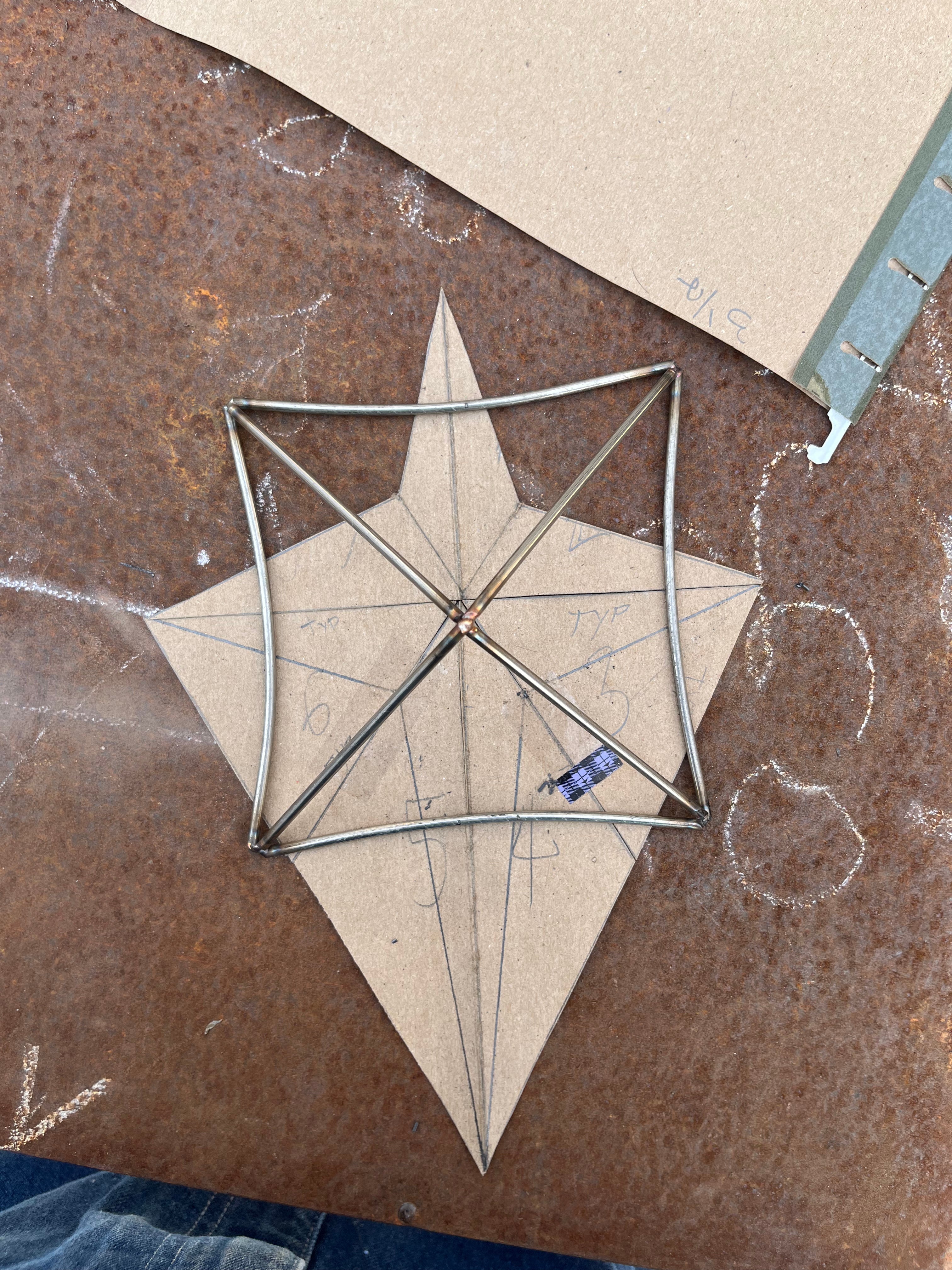

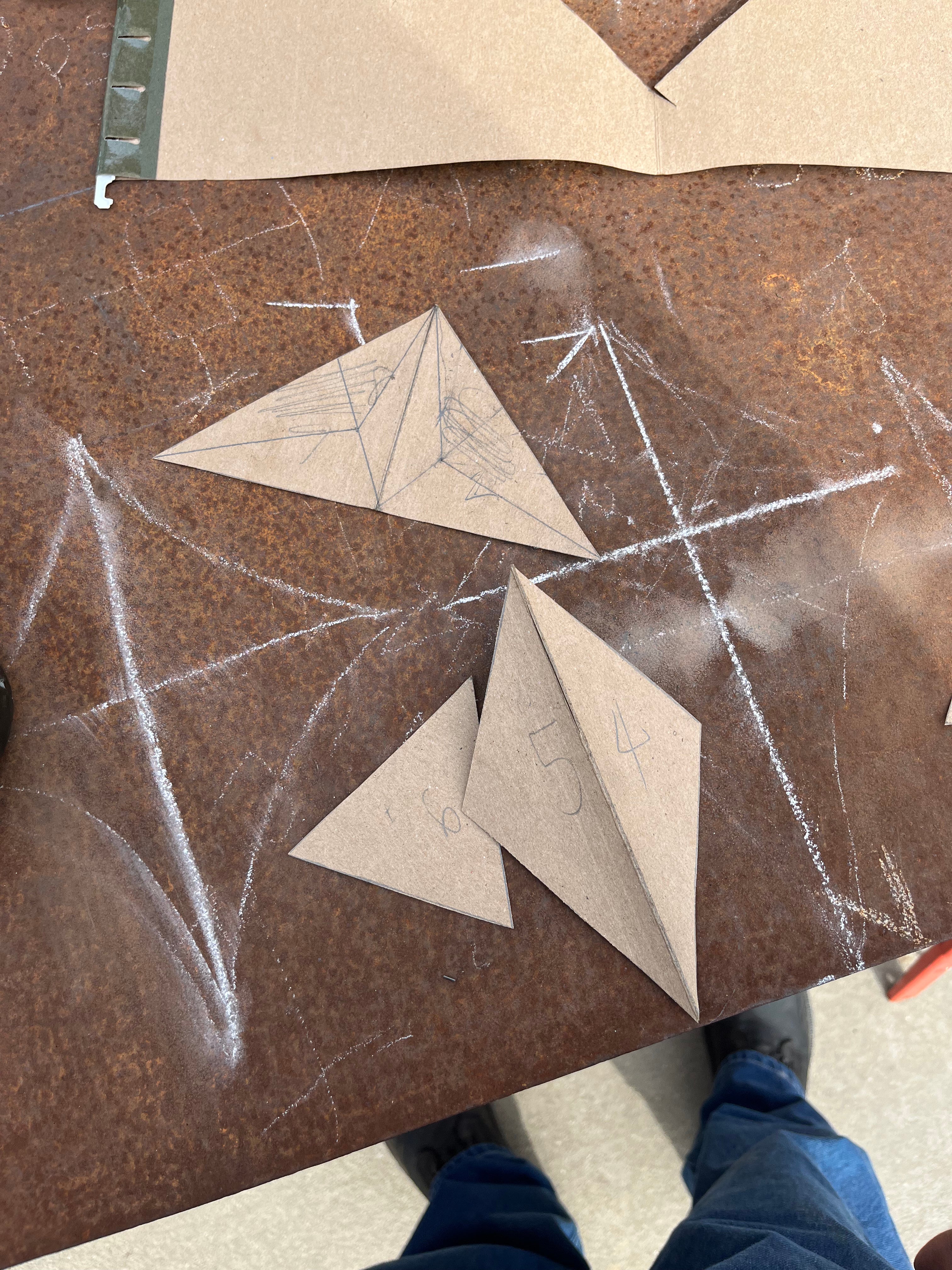

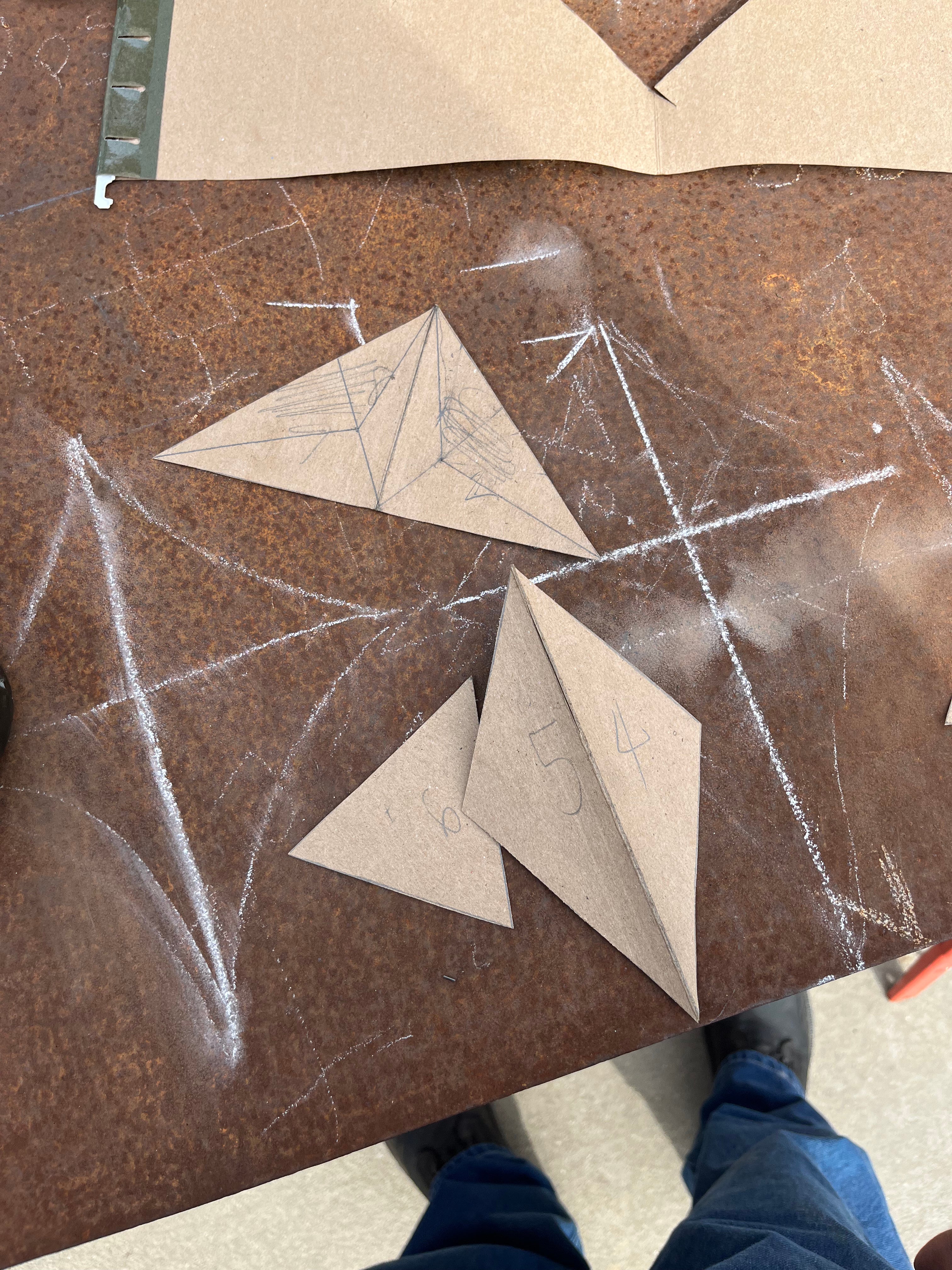

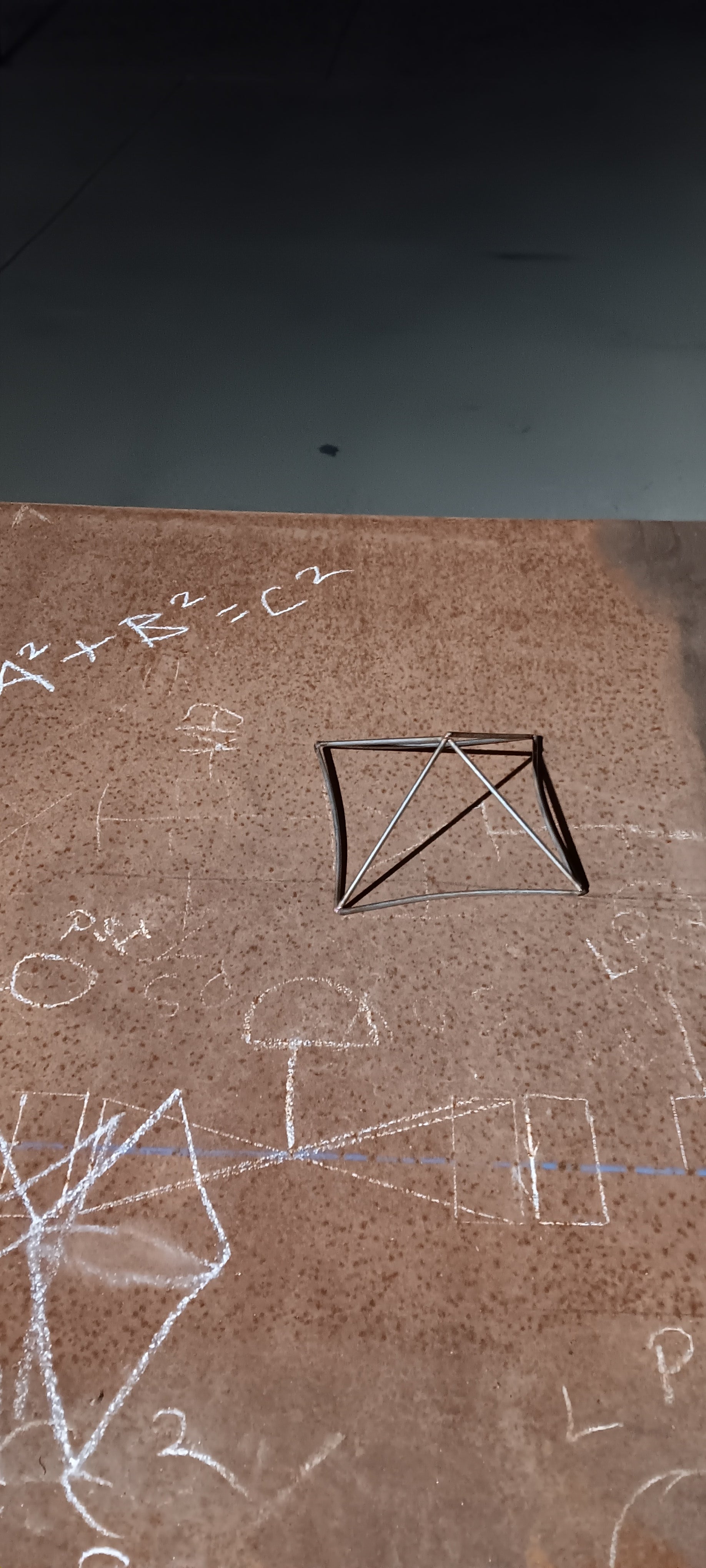

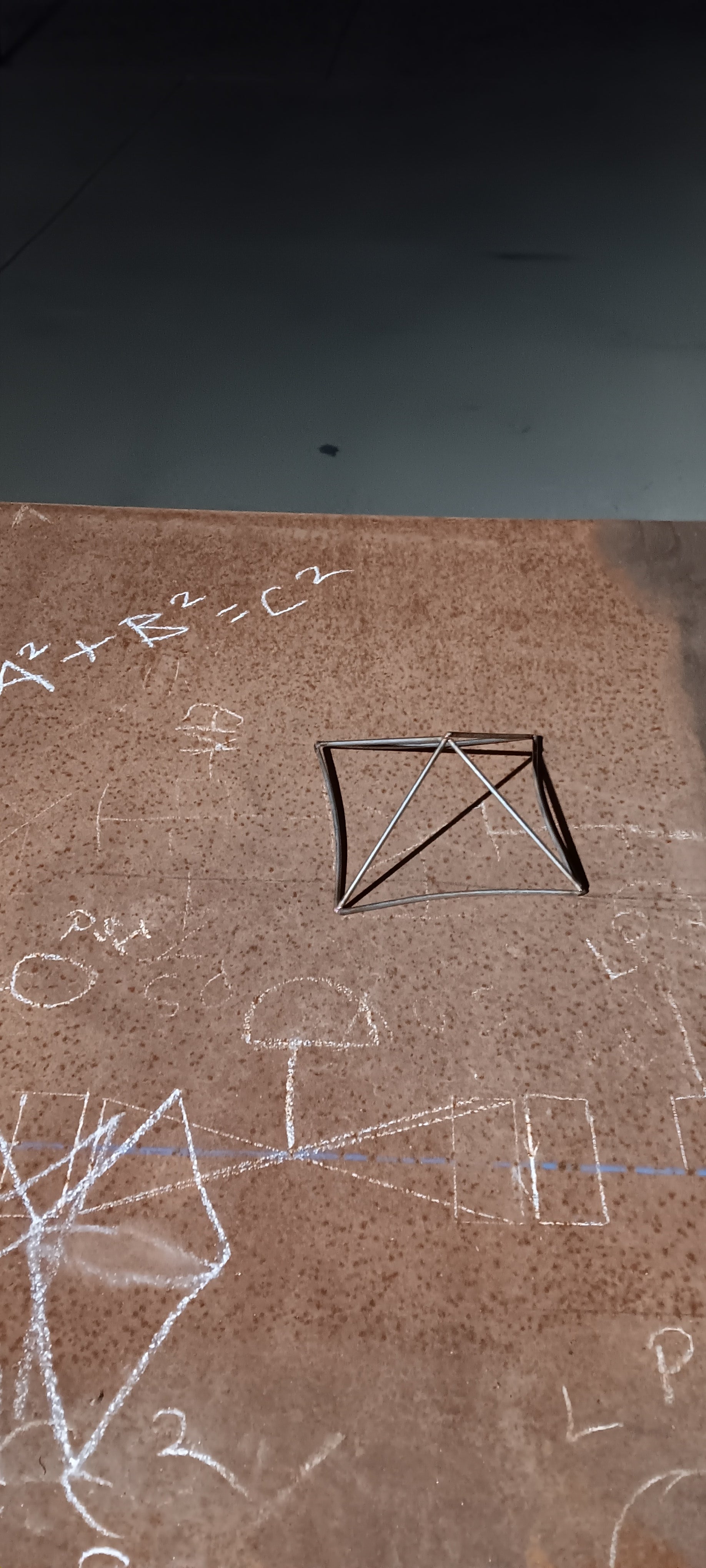

This is my first attempt at 1/4" aluminum outside corner joints. Running 200amps, 100 hz, 40% balance and 1/8" tungsten. After successfully welding out most of these mirrored 3 sided pyramids, I all of a sudden on the last half of the last weld had issues with blowing a hole in the outside corner joint. I let it cool, ground and cleaned the damaged area and tried again. Because of the increased width of the weld joint I decided to weave, but as I got close to meeting up with the previous weld things went sideways on me. Erratic arc, very hard time forming a weld pool and lots of porosity. Pictures are attached. Any advice would be greatly appreciated.

This question is for JODY COLLIER since I joined this forum after watching YouTube videos hoping to learn from you. I have a body shop and I make rust repair panels and weld with my millermatic 135 all the time. I have never been taught a single thing about welding and never really got better. I mean I can get away with mig welding but I want to Tig and grow my skills. So I have been practicing like you said running beads and I can't seem to do anything decent on steel but am able to find myself creating better and better welds on aluminum. I need to understand why even when I'm following your parameters for 1/8 steel my welds are grey and my heat affected area is huge having no thin edge I guess the cleaning action like on aluminum. I am a very beginner to Tig with that being said where can I get the information I need to weld steel better? Can you help me. Thank you for your time. A couple of pics one because if you can weld the blades that's cool and the other to show you my struggles in hopes for your point of view

My miller 135 mig machine has started acting up and I'm not sure what this is all about. Sometimes the weld is full of holes and once I stop pulling the trigger the weld puddle will grow a snake deal like the old fireworks for kids, it's behaving like there's no gas. The nozzle is dirty I've tried to clean it up but it seems like maybe a new nozzle is in order. What cause this type of malfunction? Any answers would be helpful. Liner? Wire corrosion? Nozzle? Gas issue? See the large hole inside? Now I have to cut that out and get the weld in there correctly. But this is frustrating. Thank you welderskills JODY COLLIER

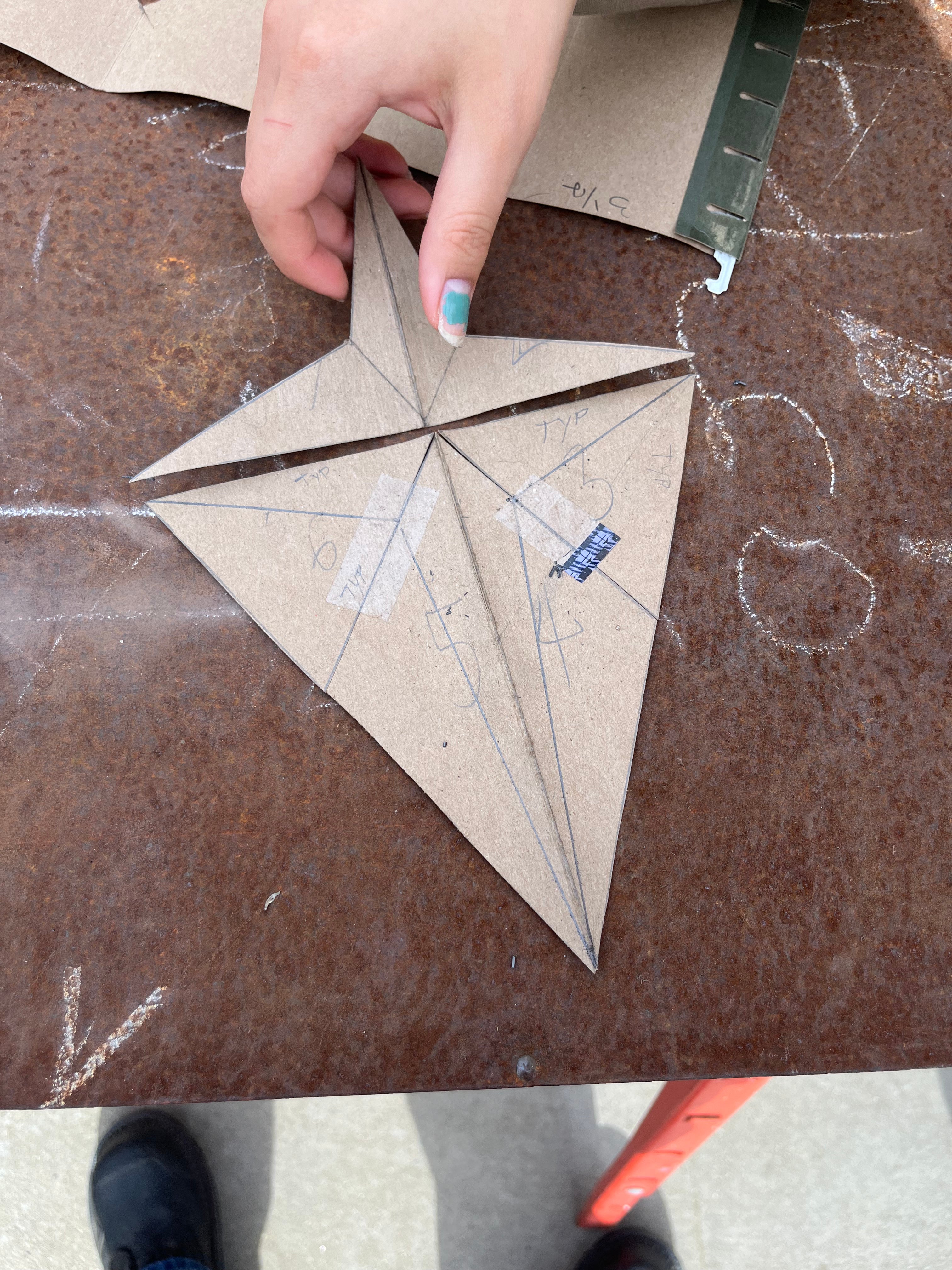

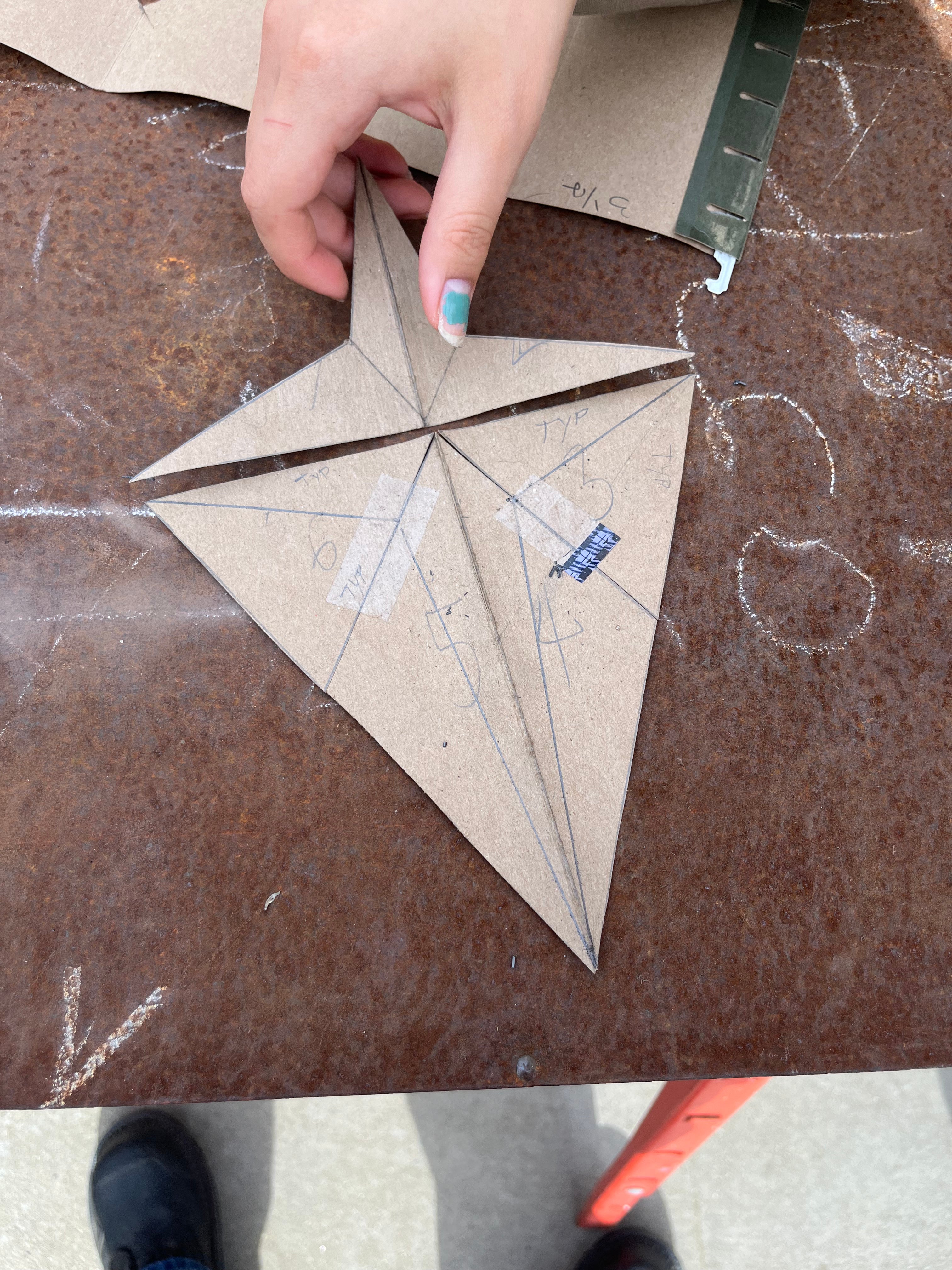

Ok , to be honest after laying out the cardboard cad, I I thought this was gonna look sharp, then I started matching up the and and cutting things out, next thing I knew I was squeezing and tacking, beating and welding. lol , it really was a fun ,easy and affordable project to create . Learned a bit about fit up, chill blocks (used a 3x3 aluminum angle to weld all panels) filled gaps with silicone bronze., and best of all its was done with my daughter, she actually engineered the whole thing, gave me a sketch and we work together to build it.

Question

1) silicone bronze don’t work on dirty steel right?

2) what the quickest way to clean off the old peel on stainless steel, you know the protective cover.

3) does the sili bronze filller flow like mud, or was I completely doing it wrong

Happy holidays

Brad Goodman Matt Hayden Shaun Graham

Brad Goodman Matt Hayden you guys ever fabricated with a slip roller, if so can you share your experience.

Allso, working plate and sheet metal is so different, especially with out a sheer, if you wanted to cut multiple small shapes with accuracy, what method would you recommend.

I'm trying to make a hoilday tree topper star out of 18 Guage, and 6 " cut off wheel. Let just say I taught my daughter the Importance of making the part match the template.

Anyhow I hope I get to post it.

Happy holidays

Decided to teach myself TIG. I have found loads of info on various sites including Welding Tips and Tricks.What I have not found is,What does a proper weld look like? For example how wide is an ideal bead ? With and without filler.Aluminum and steel.

I was listening to a podcast the other day. They had a man named Bill Newell on, and he was absolutely death on walking the cup. Something about lack of fusion between passes, from sharpening the tungsten down to a needle and tipping the torch way back. I can kind of see what he’s talking about, but I thought it was sort of extreme. Curious about your thoughts and experience.

I'm doing some 1/8" 5052 & 6061 aluminum but welds and they are cracking at the beginning of the weld. I've been able to minimize the cracking, but not eliminate it. I know the cracking is caused by heat/cooling cycle, but I could use any help I can get to eliminate this problem.

Question for the instructor crew.How wide should a tig bead on steel be when not using? Trying to gauge whether or not what I am getting is appropriate . I know I need work on keeping them straight .JODY COLLIER