Maybe get JD Brewer to do a quick video on his steel sawhorses? Hinge part number from McMaster-Carr would be great.

I found the real amazing blaze on YouTube see link below. JODY COLLIER should interview him for the podcast. The guy didn't know he was famous until 8 months ago now he started two you tube channels. He also a musician.

https://youtu.be/u-5wY4BBuR8?si=VKnAddPzWZbX8Kqu

Hi everyone,

My name is Kyle, I’m from Melbourne, Australia.

I’ve recently learning aluminium tig, I’m about a week in and I can’t get enough!

Loving all the content on this site!

I have a question on weld penetration for aluminium.

I’m just wondering if there is different “ideal” penetration welds for different applications?

-Such as something you want to be as strong as possible, obviously requires full penetration.

-where as something maybe not so structural, example: Brad’s dog feeder boxes maybe you would want less penetration to have a clean finish on the inside?

I’m not sure if I’m on the right track here, maybe once you are good enough, a full penetration weld is just the norm and second nature.

If this is the case, it would be cool to see different examples of levels of penetration and the best way to go about achieving that particular finish.

(On all of the main metals, not just aluminium)

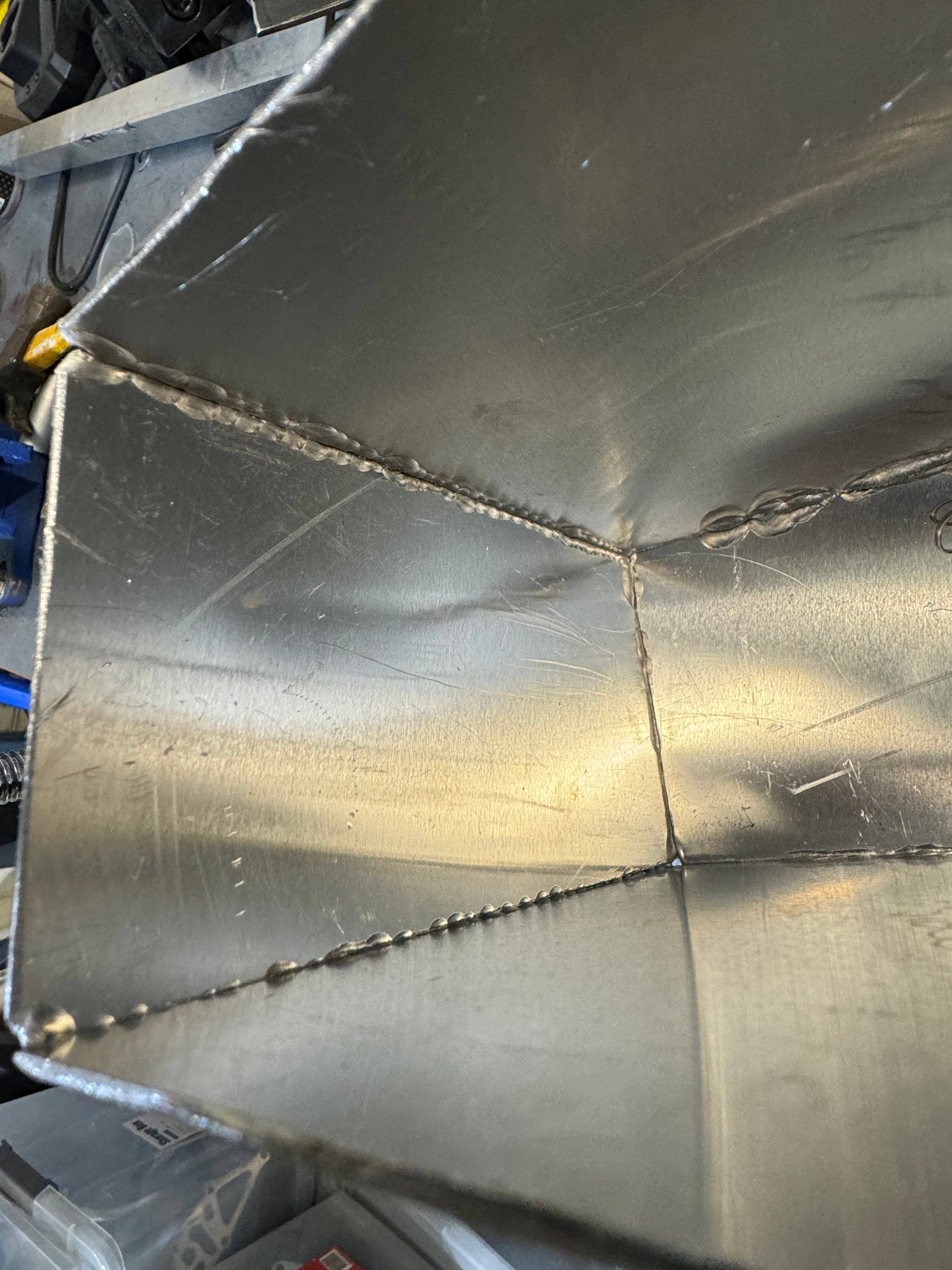

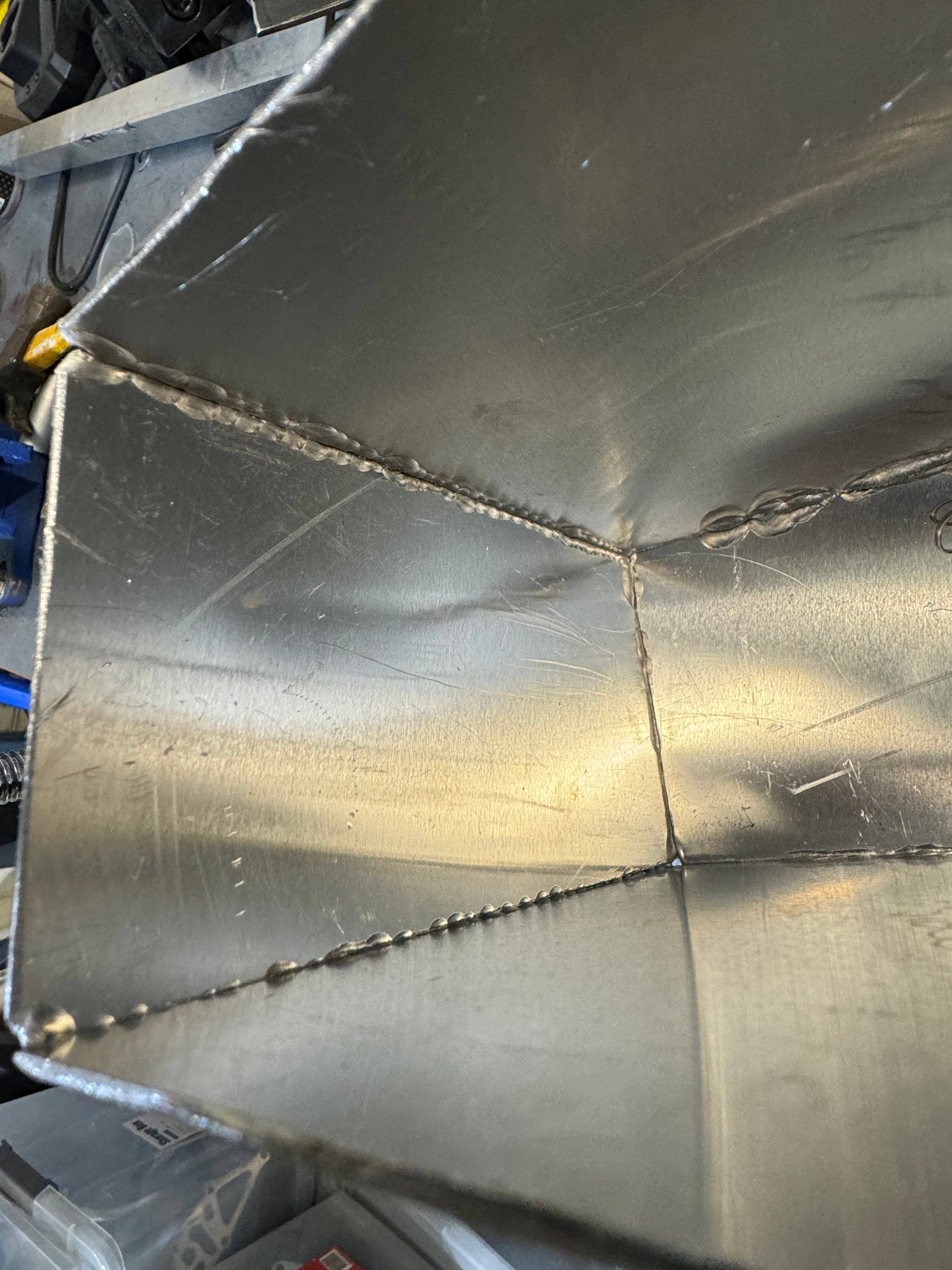

I have an example of some of my practice - I’m still learning to feed rod, that’s definitely my limiting factor. Sometimes I can’t keep up with the weld and I panic then it doesn’t go so great.

I am padding beads to get it up to speed.

I’m just wondering also if this penetration is what you would expect on an outside corner weld?

2mm Aluminium sheet - outside corner

~120 amps (140 amps on machine, foot pedal)

120hz, 30% cleaning, 17 torch, gas lens + 6 cup, 15cfh, 2% lanth 2.4mm tungsten

1.6mm filler rod - I found that 2.4mm filler was making my bead too high and cold looking.

Again, loving all the content on here! And really appreciate all instructors taking the time to teach us their tricks!

Cheers

Would it be possible for you to put together a video on what a tig weld should look like? I guess the criteria will be different for different materials, but things like the height, width, and the profile of the weld, color, sheen, start and end of weld, heat affected zone size, types of defects that we should look out for and how to fix them. I know that you guys are making great welds, but what things exactly should we be looking out for when we judge our tig welds? Thanks

Requesting a video on measuring tools and fitting techniques. Like using a speed square, combination square, etc. I had to make a handrail at work with a bunch of 45 degree angle cuts and it was a pain in the you know what. The Forman did not even know how to fit it up. 😂 I will add a picture. Video in the general area.

I’m reading the Hobart Pocket Welding Guide and read up on metal cored MIG wire. Pretty interesting stuff for the right application. Fusion and penetration vs short circuit solid wire is impressive. Would be cool to see a topic on this if the staff thinks it’s worth it.

Use this channel to give our instructors ideas on what you'd like to see! We obviously can't meet every request, but it's super helpful to know what everyone is looking for so we can make adjustments and focus on important topics!

Brad Goodman

Would you maybe make a video about the Gas Lense vs collet body topic? That be awesome and a cool topic. I would love to hear your thoughts.

Roy Crumrine a cool Video topic would be your long time experience about your Fronius. I got mine for a while now couldn’t be happier. But here in Europe we have so many manufacturers… I would like to know how she compares to the US Market where are mainly two Manufacturers. Btw, your Instagram page seems dead / deleted