Just got my first engine drive welder from a weld supplier Encore in southern California. If your ever in town or live near by its definitely a weld supplier you wanna visit.

Signal hill California

Ontario California

And Valencia California.

Let's see your projects! Start a post describing what you're working on and show some pics and videos! Let's help each other out with that build, repair, or modification. Credit to WelderSkills member Michael Kearsey for the idea!

Good updates on Jody for those interested:

He's doing much better! His doctors are very happy with his lab results - he's staying very active and getting his strength back. The finish line is still a good ways off, but things continue to trend in the right direction.

For now, his treatments are less intensive, so he's able to go home every day and live his life - editing videos and working on Weldmonger stuff. We're feeling good about everything, and the road ahead looks clearer every day.

A huge thanks to everyone who has supported him through all of this. It's been pretty incredible to see!

Recently became aware of these Knipex mini bolt cutters. Man, they make cutting 1/8" steel and stainless filler rod so much easier. No more Welpers for me. They'll be on the MIG cart where they are best suited. At fifty bucks, I think they're a bargain, considering they're a high quality German made tool, not some Chinesium POS.

Edited to correct the price. I paid around $50 not $30. They'll outlast me, so I think its still a good value.

Hey everybody, I have a rather unfortunate announcement to make.

We're gonna be closing WelderSkills in late July. Many of you have likely noticed that things have slowed down a bit around here lately. That's largely because my Dad (Jody) is currently in the hospital receiving treatment for a rather serious diagnosis. He has a long, hard road ahead, and his treatment will require 100% of his focus for the foreseeable future.

Closure is certainly not what we'd like to do, but without my Dad's contributions (both on camera and behind the scenes) WelderSkills just won't be getting the attention it deserves, and won't be able to earn your membership fee every month with new content. WelderSkills is a product whose quality we are committed to maintaining. If it's beyond our ability to meet that quality standard, then we don't feel right in offering it to you all.

For those of you who have signed up with an annual membership after July of 2024, I realize you won't be able to get your full year of access. For that reason, I'll begin processing prorated refunds very soon for members who won't be getting their full year (For instance, if you signed up last October, you'll receive a refund for 3 months of service). If you signed up for an annual subscription using the App Store or Google Play, send me an email to get your refund because that process works a little differently (joey@welderskills.com).

As a thank you for signing up with us, our full course library (Intro to TIG, MIG, Stick and mini courses) will be made available to download until we close the service for all active members. Aside from that, the WelderSkills service will maintain all functionality until we go offline.

Thank you all so much for giving this thing a shot. I had a great time working on it, and please believe me that this announcement absolutely sucks to make. It's truly been an honor and something I'm really proud of building with my Dad, all of our awesome instructors, and each of you.

-Joey

Feel free to comment here or email me with any questions at joey@welderskills.com

I'll continue to post updates as I have them!

EDIT: moved to new channel 'WelderSkillsClosure' where I'll discuss all details related to that!

More machining than welding, but got to at least weld a little today. Turned a slug, and milled a square hole in a round peg. then welded a piece of tubing that the end of a shaft will eventually fit inside and be welded. This will ultimately operate the oil valve that feeds the burner of a steam locomotive boiler. Got to try out the TIG function of the engine house's Miller Multimatic 220. It seemed to make a nice smooth DC TIG arc. I'd stick welded 7018 with it before, and it did that well(but I don't believe it will run 6010.) I was happy with it, considering it was the first TIG bead I'd ever ran with it.

!/8" wall tube to a square socket made of 1045. Pre-heated the 1045, and welded at 150A. ER70S-2. There's a 1/2" long stub that the tubing is pressed over to locate it, so it had a nice heat sink behind it.

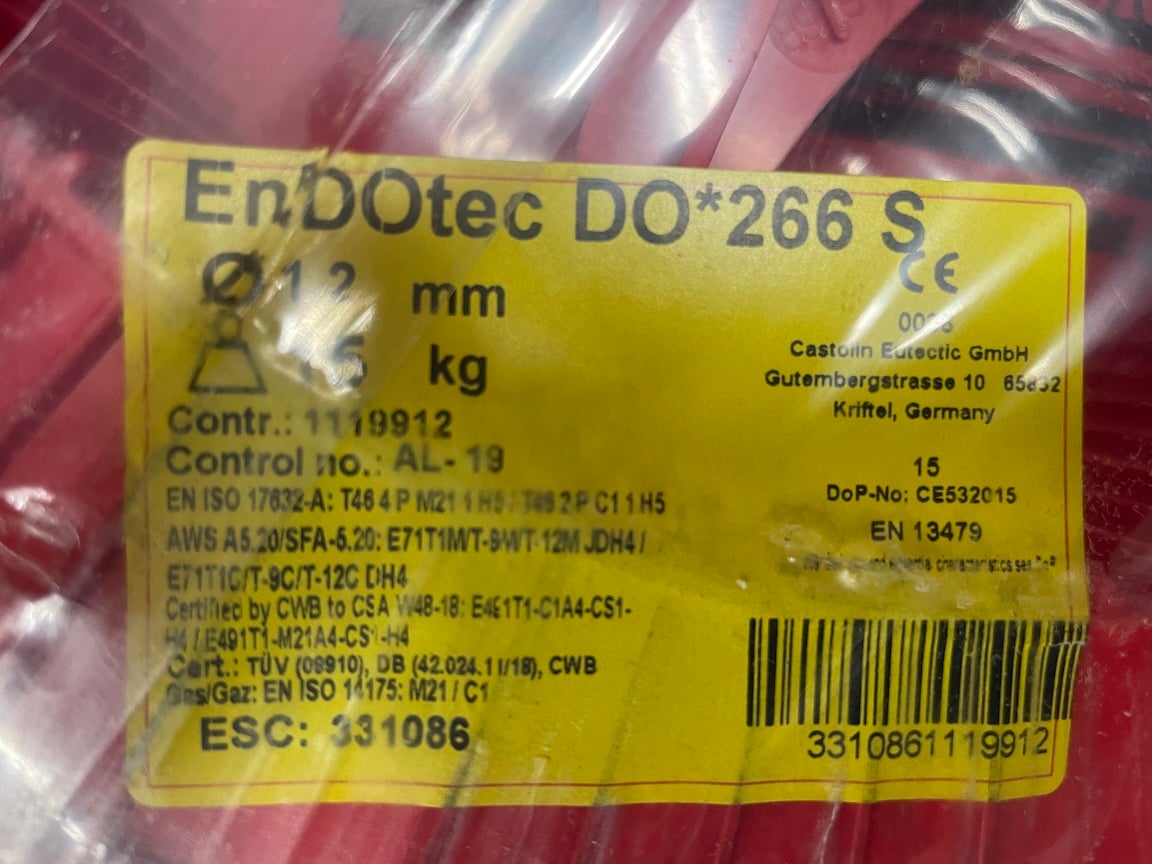

Tagging Matt Hayden as we'd communicated earlier on dual shield questions. Wasn't happy with the performance of the Lincoln 71M dual shield wire I tried. No matter what I did, there was random worm tracks, lousy root fusion in 1F, and man it was smoky. Decided to try another flavor and wow what a difference. This is Eutectic DO266S set at 25V/250 IPM 40 CFH 75/25 gas. The first thing I noticed was a fraction of the smoke, and no worm tracks. Wet in really nice. And even in 1F there's root fusion. Very promising. Still need to get used to it. Definitely need to slow down for more fill, and shift my aim up a little, as I'm favoring too low in the fillet. This may end up my go to dual shield. It's a little spendy at about $8.79/pound, but it works.

For anyone who wants an update on Dad's health, he made an announcement via YouTube today.

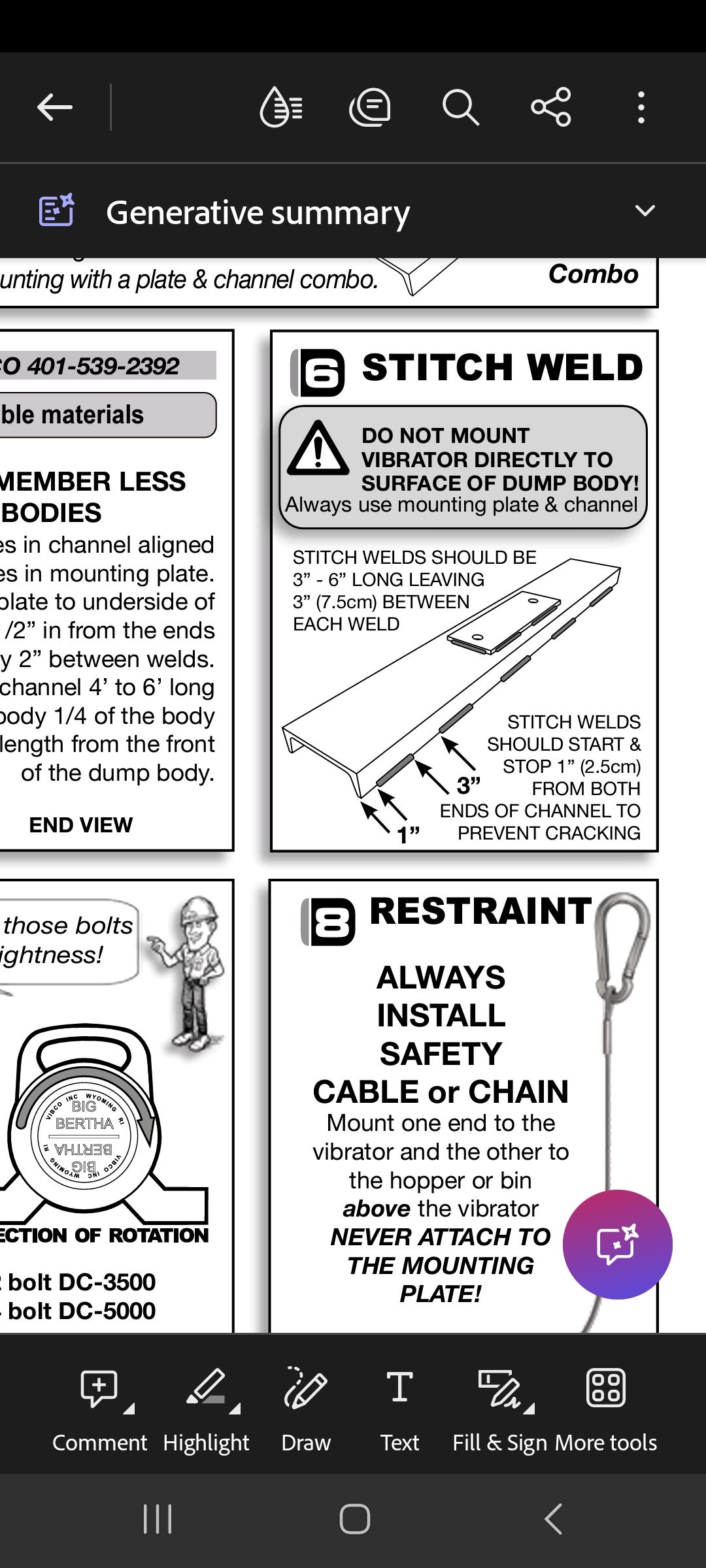

I need to weld a channel bracket on the bottom of my dumptruck bed. This is to mount a electric vibrator to clear out the bed when dumping.

I was going to use dual shield Flux Core Lincoln outer shield 71m .045. 25v @ 250ipm. The problem is I absolutely suck at overhead. Every time I try it I feel out of control, craps falling everywhere etc. I want to do some practice first and try and figure this out.

Any advice is appreciated

Hi joey, I wanted to ask if i could download some of my favorite video content outside of the courses? keeping your pop in prayers , thanks for all the valuable content.