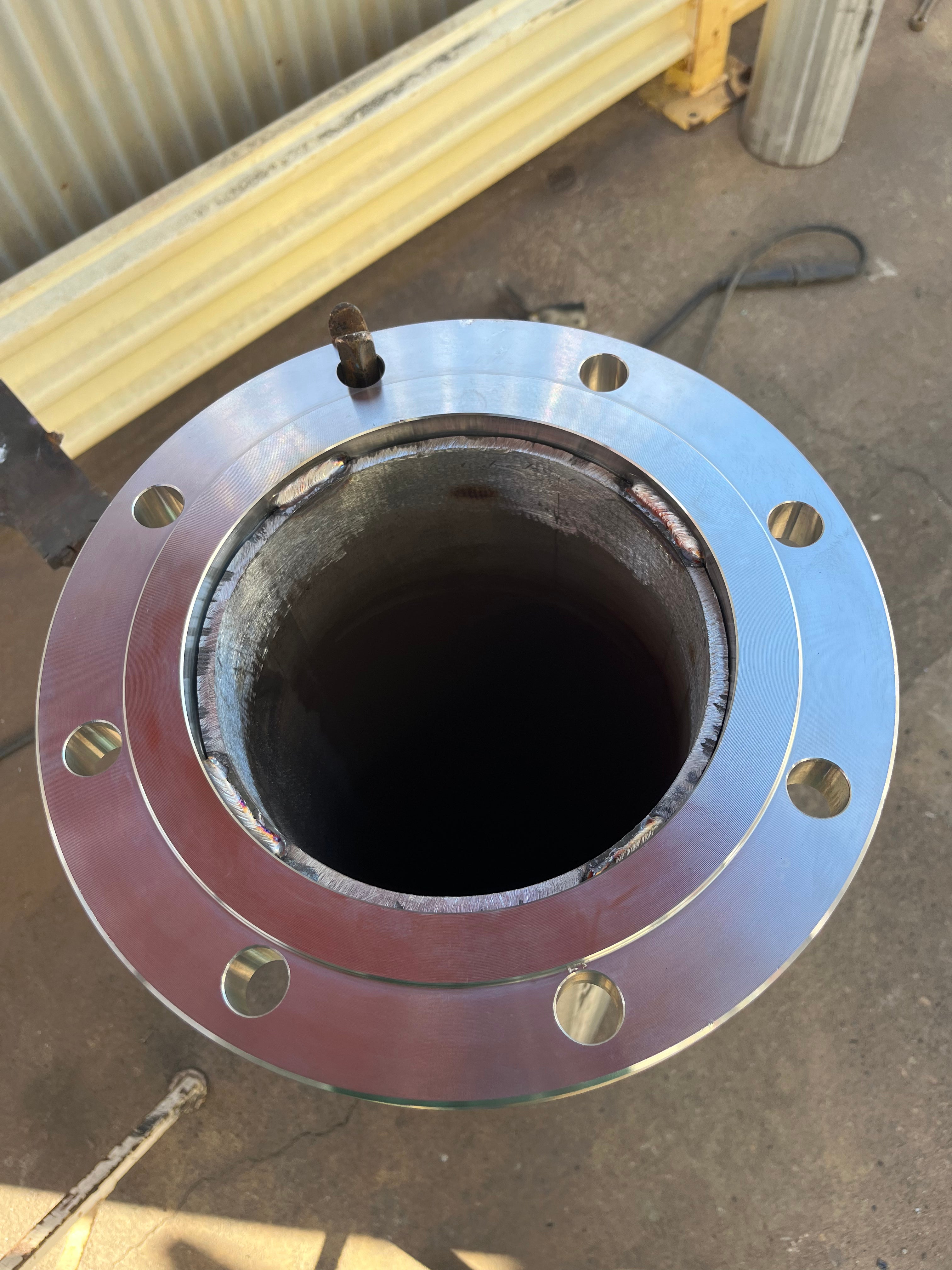

Fun little project, piping for Instrumentation air measurements. 8 pipe , 150 lb mating flange welded with 316/316L -16 1/8 rod smaw . 110 amps DC + 3 pass. Never really ran stainless stick, but I always heard the the slag has a tendency to pop off at you, the funny thing is the slag keeps popping even after you clean the weld, kind like jumping beans. Was able to find a small box rod on the store shelf for about 115 bucks.

Jorge LLamas

Posted

Commented on 1.25 hole through 1.5"

Posted

Posted

Posted

Commented on 2 inch TIG Socket Weld in Tripod Vise

Commented on Tips for Feeding Tig Rod