Just got my first engine drive welder from a weld supplier Encore in southern California. If your ever in town or live near by its definitely a weld supplier you wanna visit.

Signal hill California

Ontario California

And Valencia California.

Recently became aware of these Knipex mini bolt cutters. Man, they make cutting 1/8" steel and stainless filler rod so much easier. No more Welpers for me. They'll be on the MIG cart where they are best suited. At fifty bucks, I think they're a bargain, considering they're a high quality German made tool, not some Chinesium POS.

Edited to correct the price. I paid around $50 not $30. They'll outlast me, so I think its still a good value.

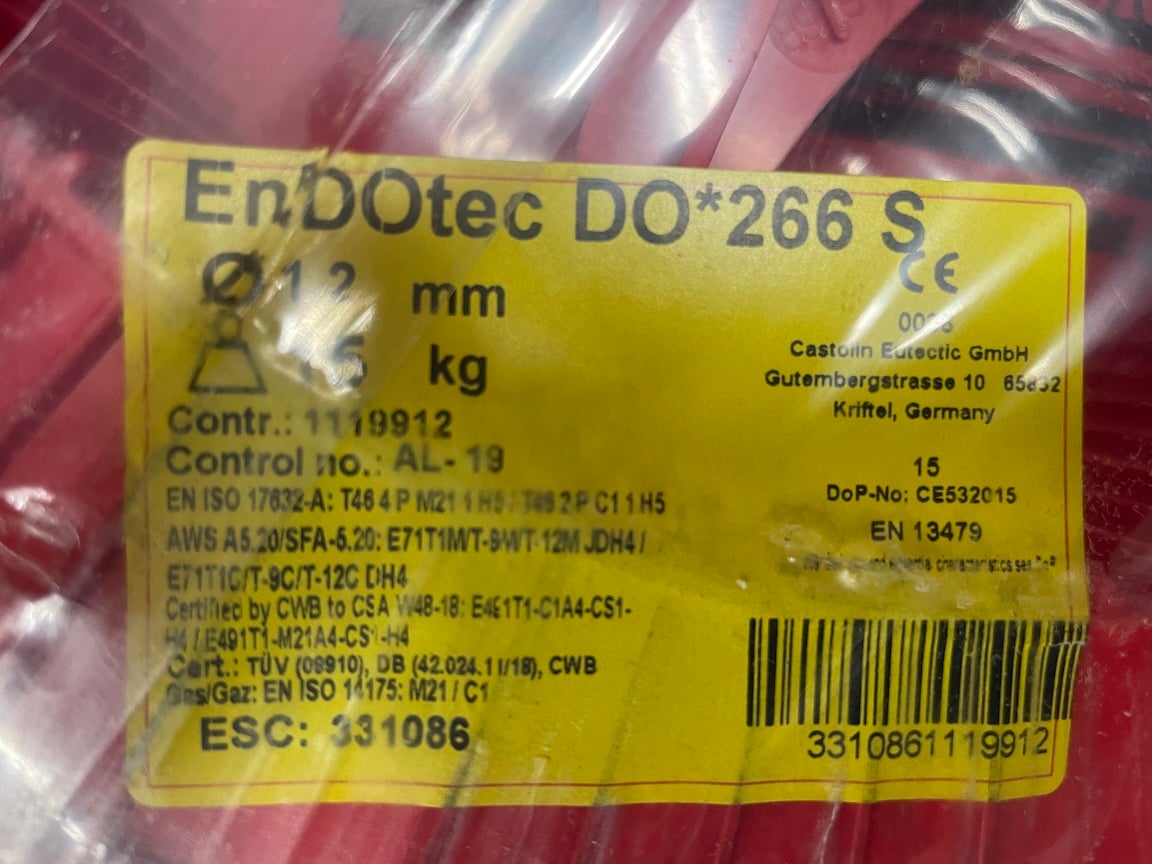

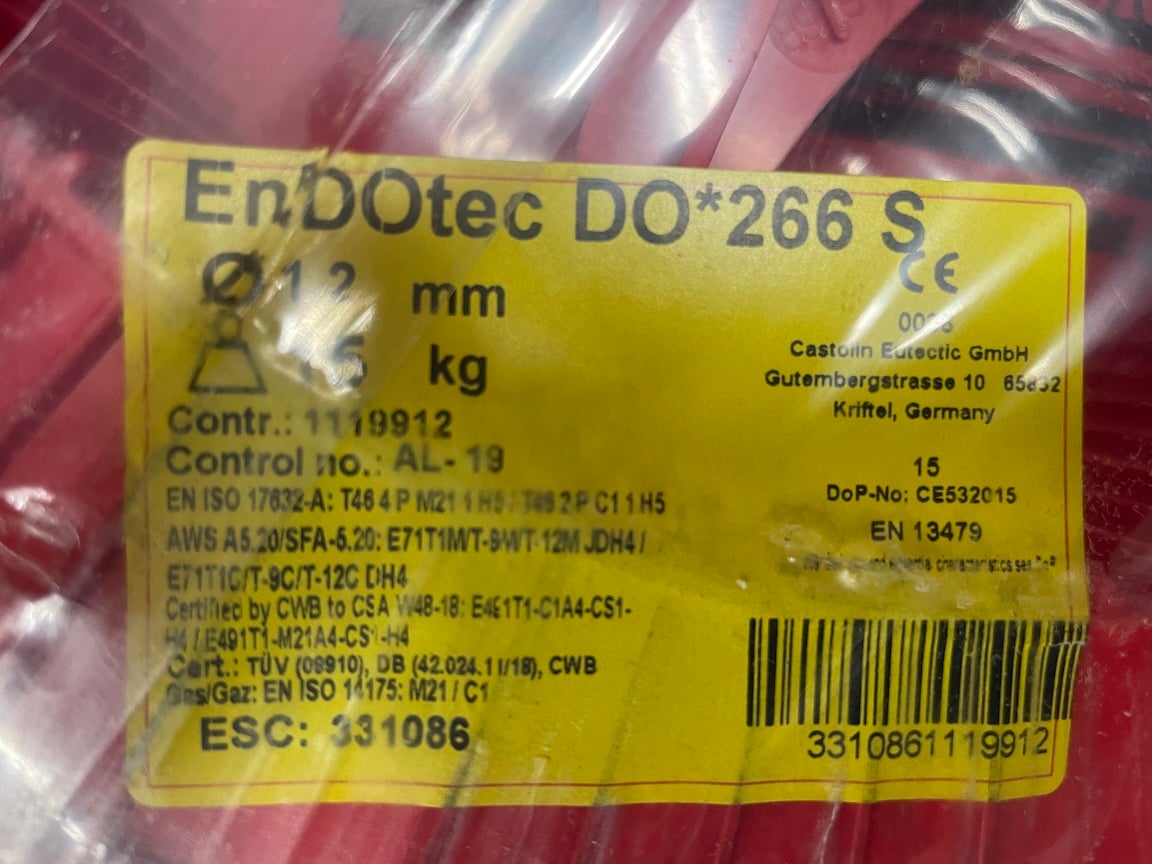

Tagging Matt Hayden as we'd communicated earlier on dual shield questions. Wasn't happy with the performance of the Lincoln 71M dual shield wire I tried. No matter what I did, there was random worm tracks, lousy root fusion in 1F, and man it was smoky. Decided to try another flavor and wow what a difference. This is Eutectic DO266S set at 25V/250 IPM 40 CFH 75/25 gas. The first thing I noticed was a fraction of the smoke, and no worm tracks. Wet in really nice. And even in 1F there's root fusion. Very promising. Still need to get used to it. Definitely need to slow down for more fill, and shift my aim up a little, as I'm favoring too low in the fillet. This may end up my go to dual shield. It's a little spendy at about $8.79/pound, but it works.

Putting a new floor in and lifting the axles on a stock trailer. Really glad it was one of my coworkers and not me that washed it out before it got brought in here lol

Need some help here. I got a .45lb spool of Stoody 101HG and I’ve been having trouble with the welds being really rough and also just not setting out well. Now I will say I noticed that the paperwork calls for 98/2 and all I have is either 100% Argon or 75/25. Unfortunately i had someone pick this up for me so they didn’t know. With preheat I can make them okayish. Is the gas the main culprit or am I just bad at it?

Happy New Year! Hope you all have a great 2025. Last night Mother Nature put on a great light show for us here in Alaska. Better than fireworks!

Quick fixturing trick with hold down clamps. Sometimes the wrong tool is the right tool. Be creative with tooling.

Hope everyone is enjoying the holiday. We plan to keep hitting it hard in 2025 with lots of new stuff. Anyone have any welding related new year's resolutions they'd like to share?

I wanted to practice on some .063 x 3" aluminum tube, so rather than cutting short pieces I decided to make pie cuts. After making 2 90's I went a step further and made a ram's head. Then a couple of saddle cuts into a cross, on to 3 more 90's of different radii. Then what the heck, put them all together. Man, did I learn a lot, like how to fill holes and the criticality of torch angle, and so much more.