last night's podcast recording is up!

Latest in the welding rig build from Sam

Sam Hagan - Welding Rig (Pa...

Sam and Aren going live this Wednesday at 8 pm EST

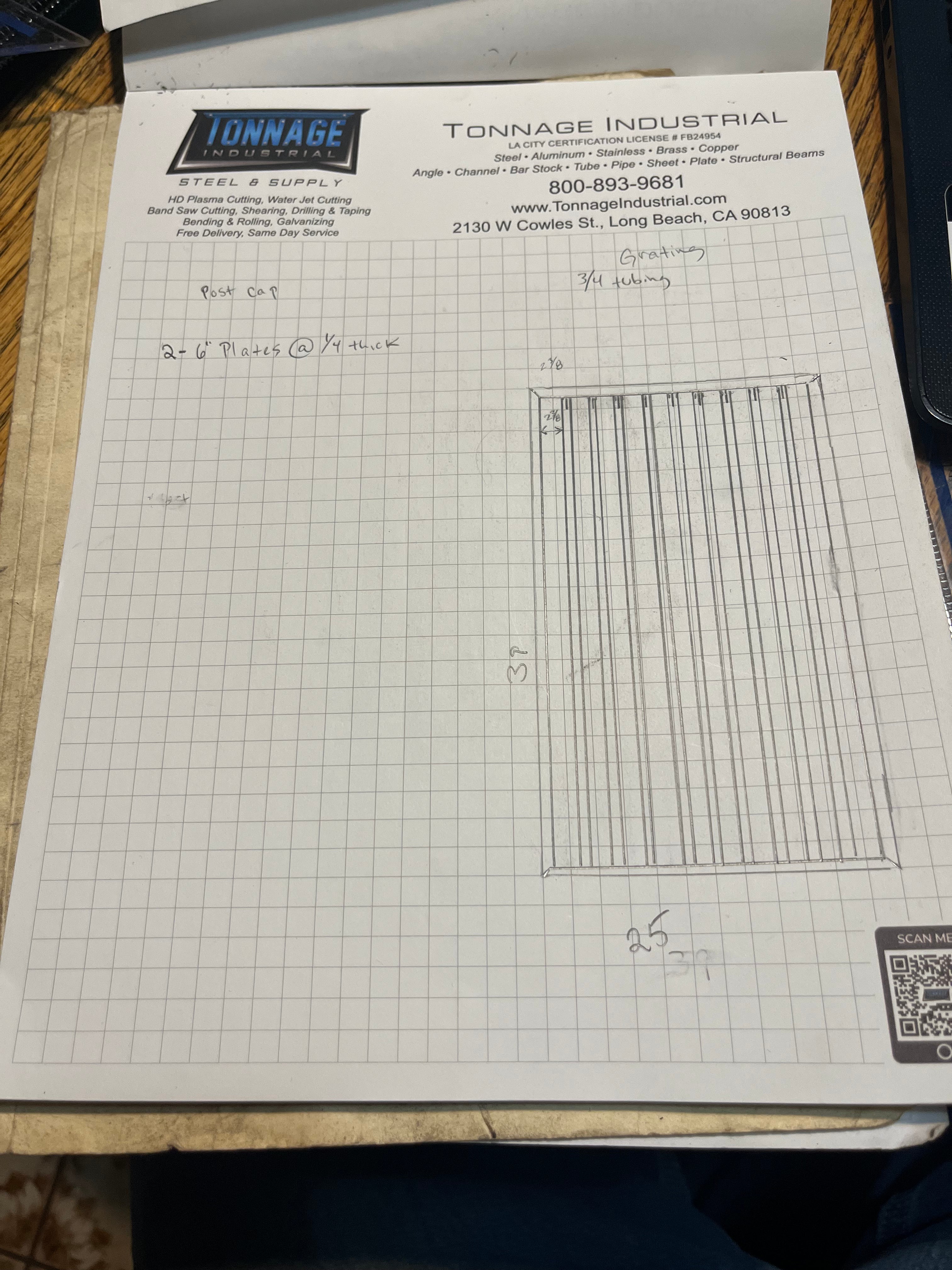

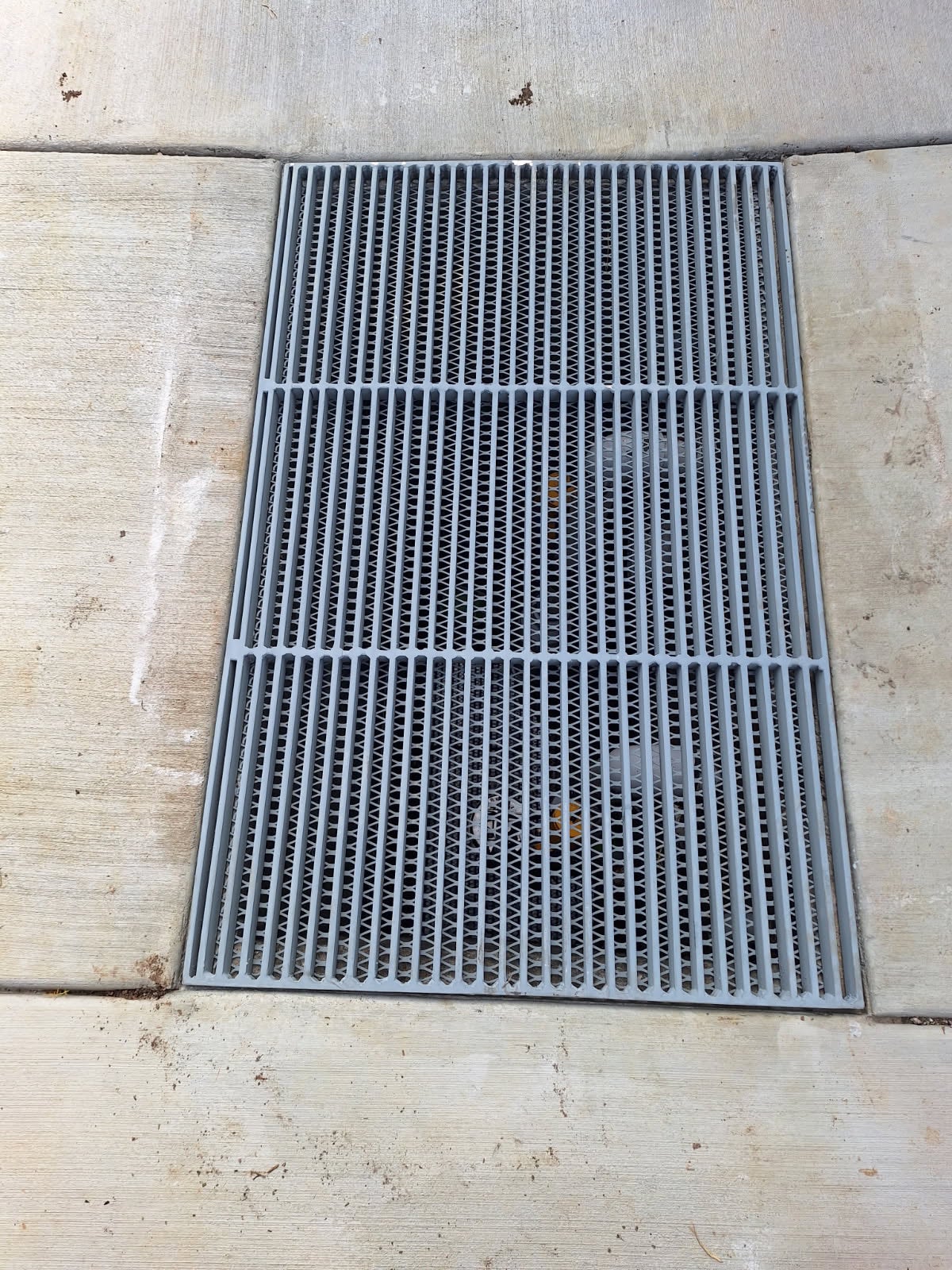

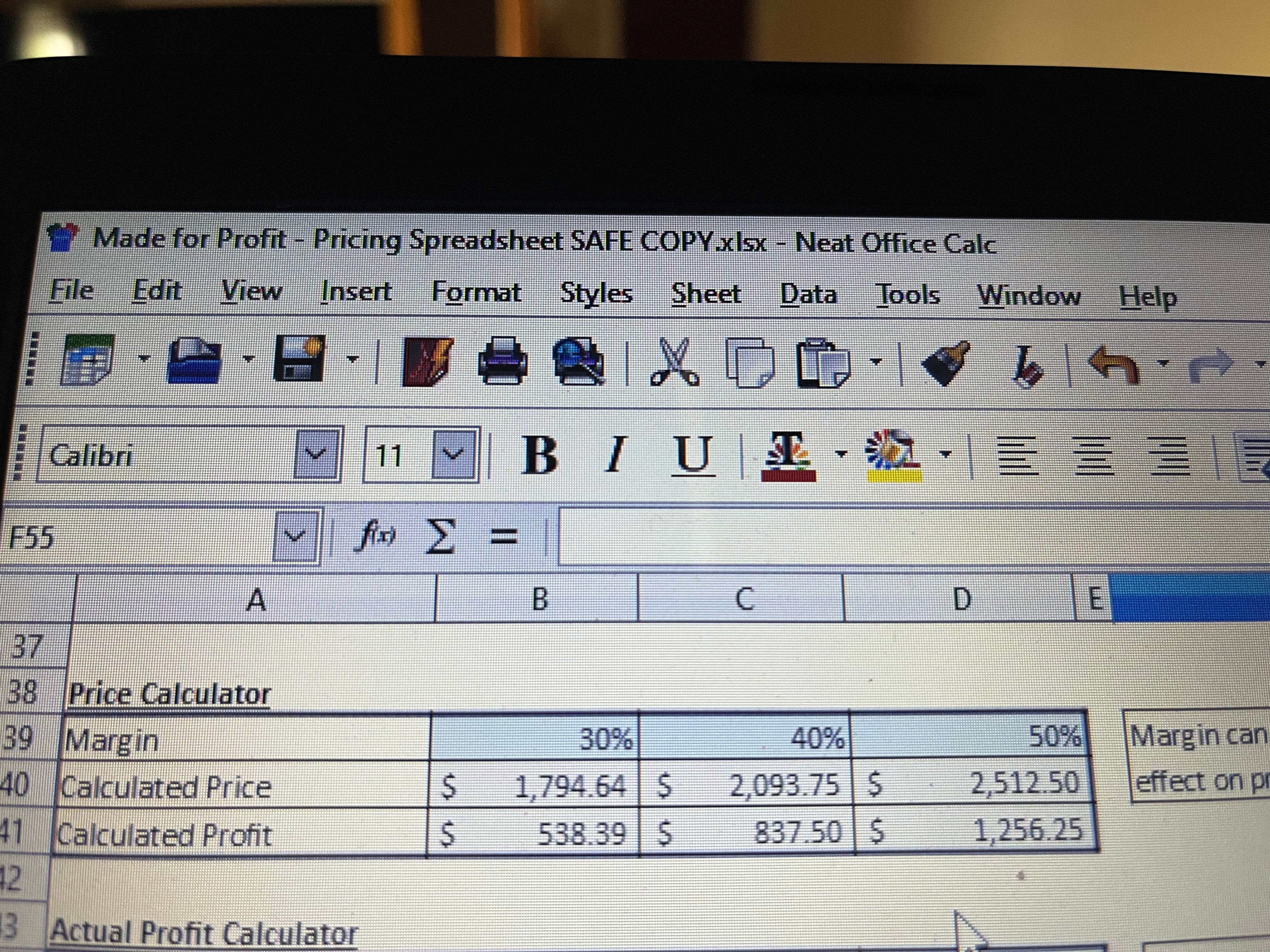

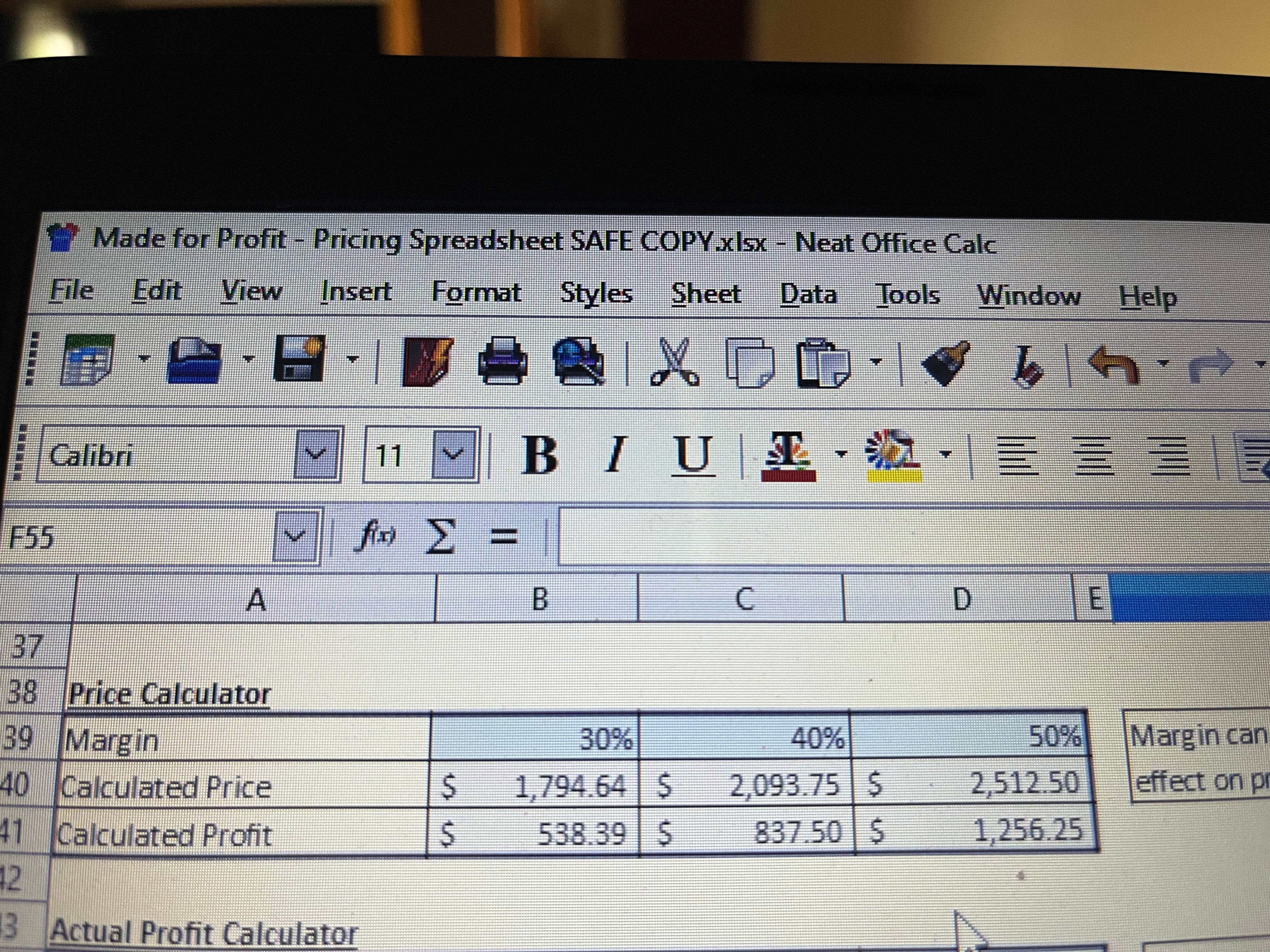

Just finished this little project building a grate for a sump pit and two caps for fence post. I couldn’t find the grate big enough to cover the hole in one piece, plus the customer asked for a screen to keep leaves out. I decided to just build one. After deciding to use flat bar instead of tubing I was able to plug in all numbers in a excel spreadsheet format I purchased from a guy @ a website “MADE FOR PROFIT “ and was able to quote the job at a 40% margin. I do this on my spare time by with these numbers I wanna do more .

The tools I used are mine , the leads are mine and the welder I used was station at my house , but when it came to being mobile, I got one from the the rental yard for 75$ a day.

I think I’ll hold off buying my gas driven welder for now.

chop saw review from Matt!

Matt Hayden - Evolution Cho...

Question for you guys that run a lot of dual shield. Do you think that "slag you drag" is a hard rule? I was padding beads of .045" Lincoln 71M Outershield( C25 gas ) at on plate today set to 25V/250 IPM. Dragged the beads left to right, and pushed the beads right to left. Darned if I could tell the difference. Just used a very slight ( 5-10 deg ) tilt either to or away from the direction of travel, with the gun pointed straight in. I haven't tried a cut & etch yet to see if there's any difference inside, but on the surface it runs great either way. Love the spatter free welds. I must admit I was wearing Crocs and never so much as felt a spark in an hours welding! I know, I know, it's not proper footwear. My shop, my feet, my rules! :)

Need some help here. I got a .45lb spool of Stoody 101HG and I’ve been having trouble with the welds being really rough and also just not setting out well. Now I will say I noticed that the paperwork calls for 98/2 and all I have is either 100% Argon or 75/25. Unfortunately i had someone pick this up for me so they didn’t know. With preheat I can make them okayish. Is the gas the main culprit or am I just bad at it?

This is a sort of a rookie question.

What would be preferred method for welding 1/2" thick structural aluminum. 6061 grade. How does everyone like to accomplish this? We use a Lincoln 350mp with a push-pull gun and 4043 filler metal generally.

Straight mig or a pulse setting? Give me some of your favorite steps to make this right. Not sure who would be best to tag-

Joey Collier,

Here's a neat new video from Shaun!

Shaun Graham - Job Planning