Had to fit and weld a 30 foot handrail with 45 degree cuts and angles. No table long enough so I had to work on the ground. Used band saw and chop saw to make cuts. Foreman did not even know how to fit it up. 😂

How would you guys go about welding the center of this? 😅

It’s schedule 40- 1.5” pipe (aluminum)

Team finished the 50 foot bridge section at my job. Very cool seeing how they moved it. My first time being a part of a project this big. Can't wait to see what kind of truck that will move it.

This is the housing of the boilers I am welding, I guess it’s a lot smaller than some other guys here are producing! ✌️

I wanted to share a very advanced technique I have been working on since I started tig welding.

Not everyone can do it, takes alot of focus to perfect.

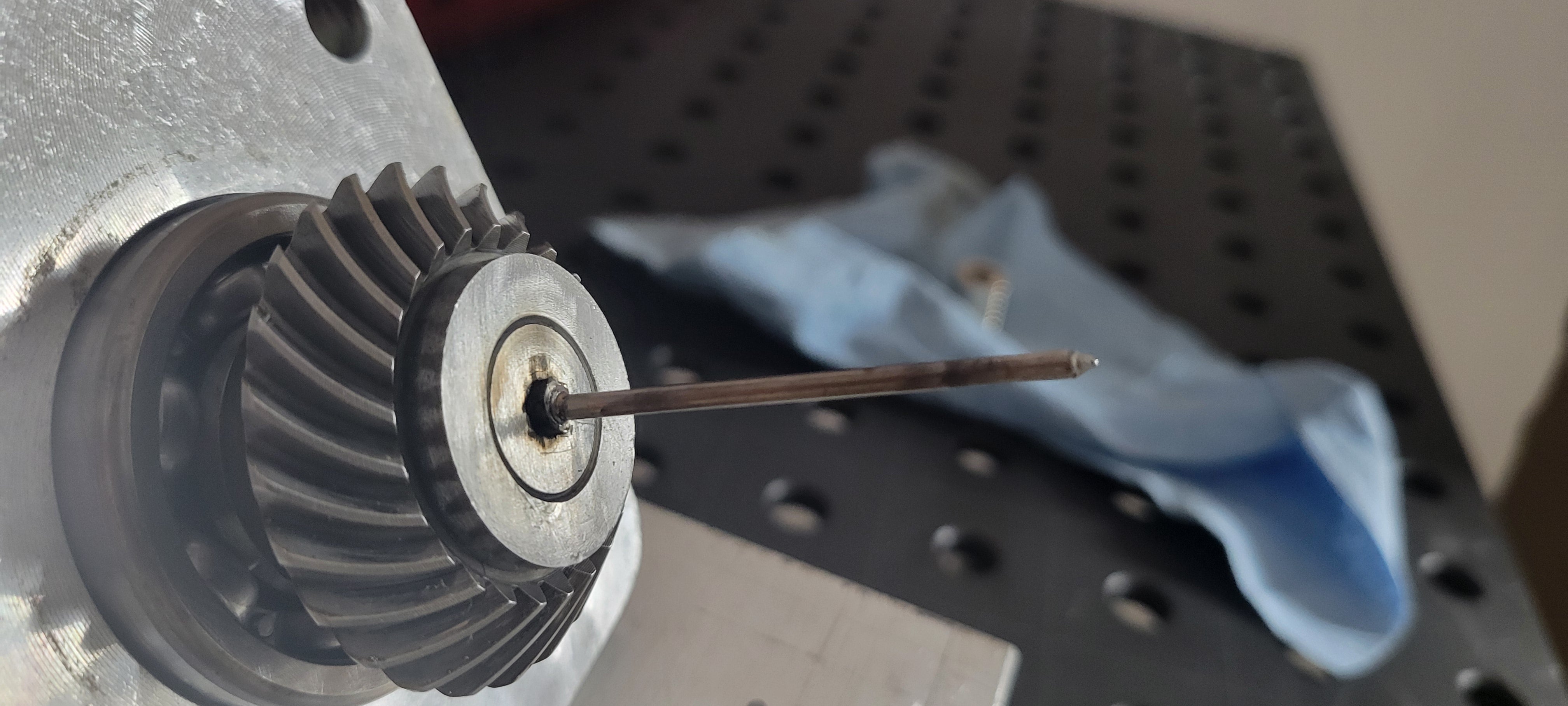

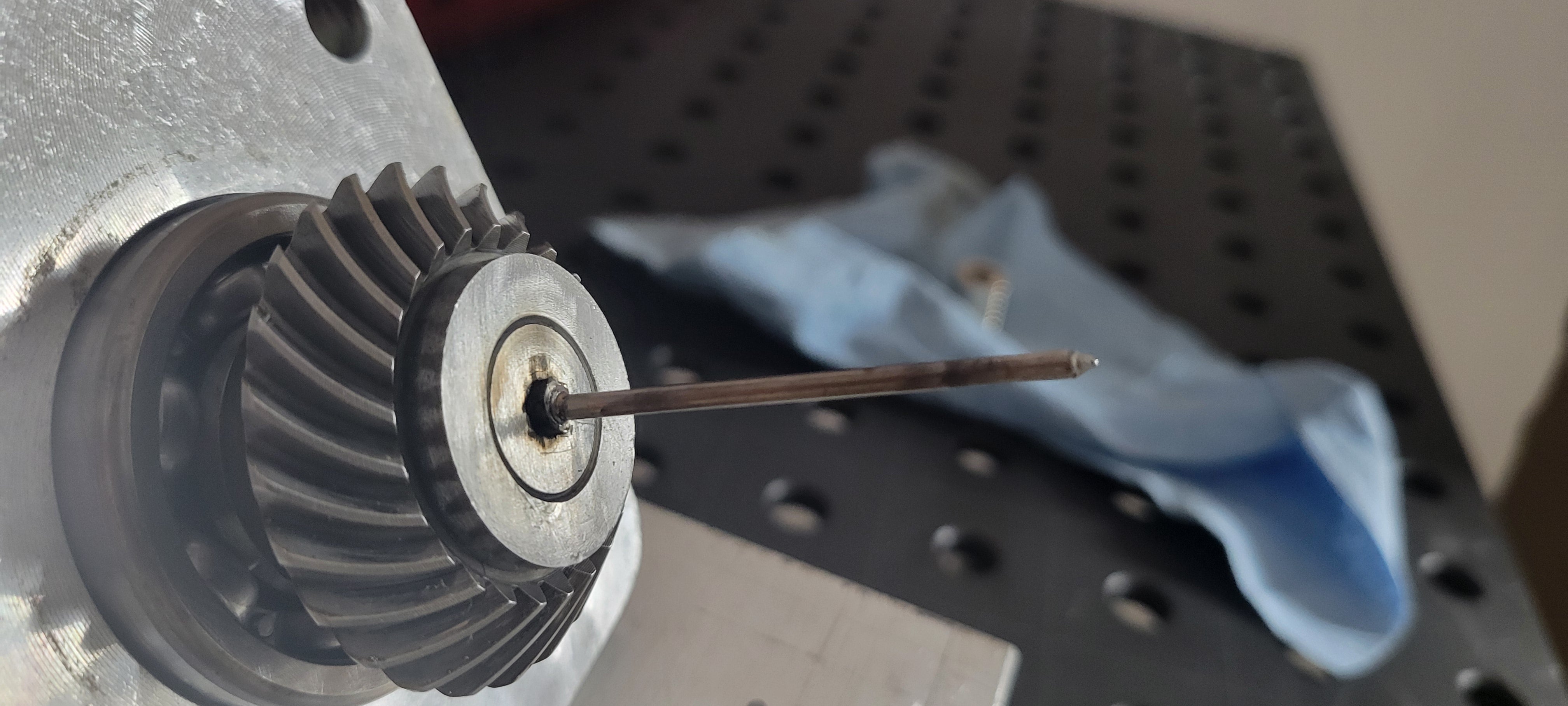

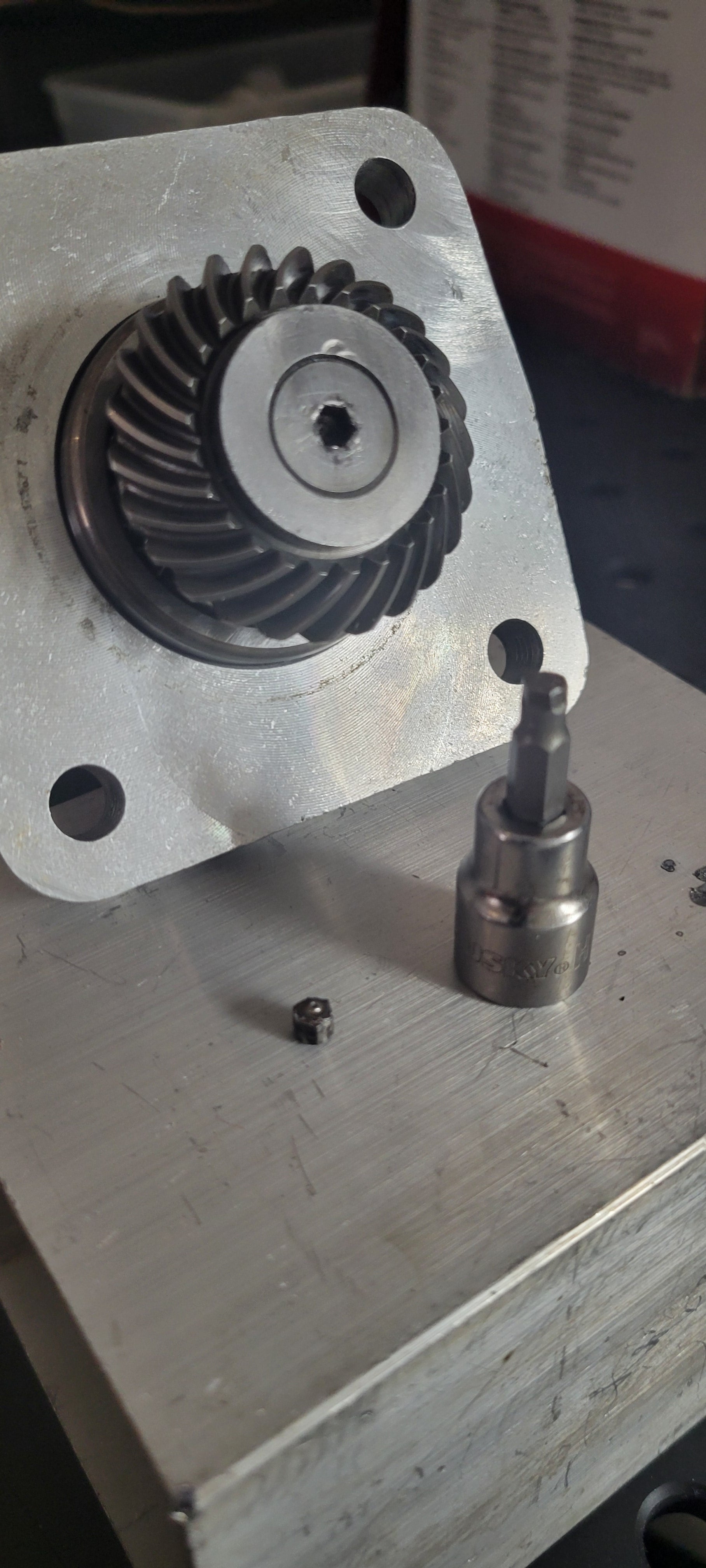

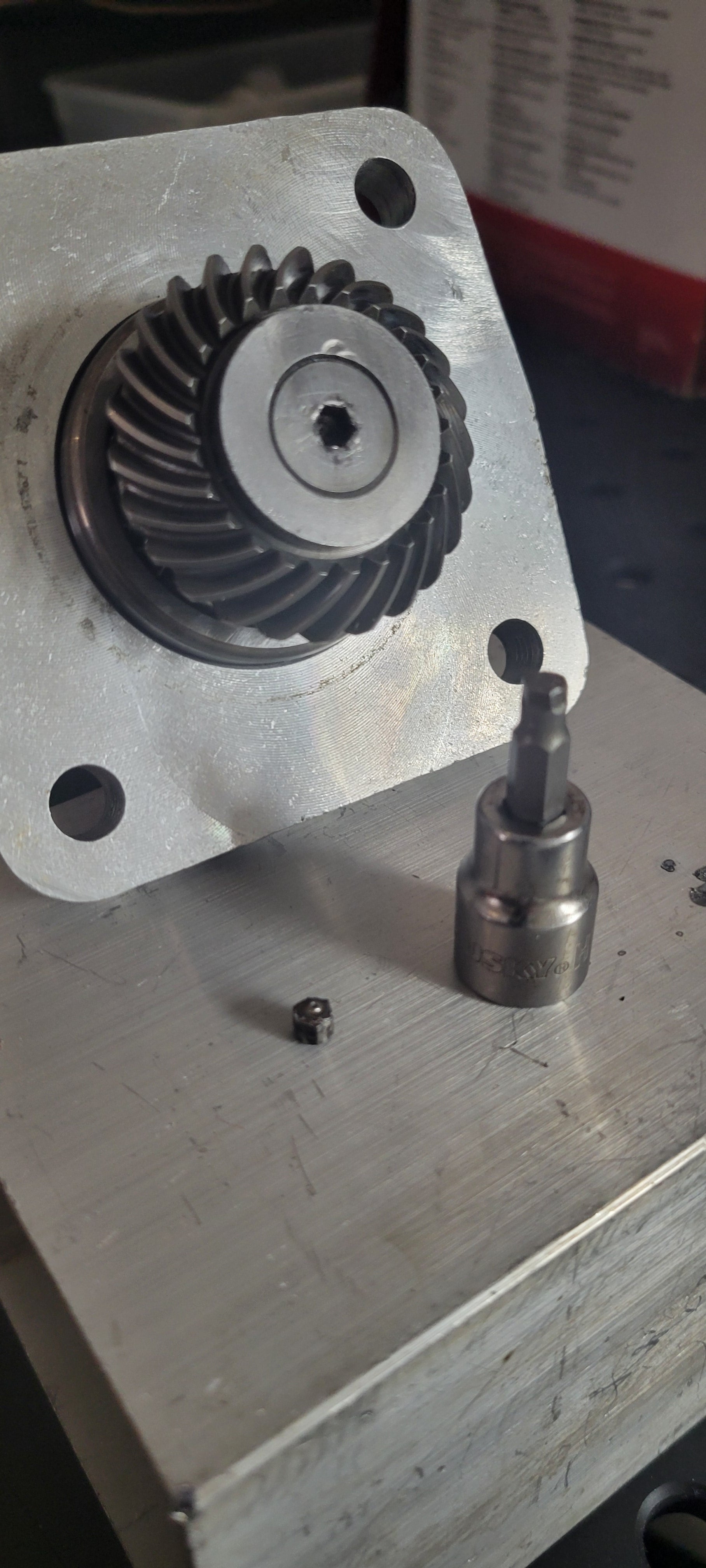

I was working on a $1500 Gearbox and snapped a hex bit off flush in a fastener. Rather than scrap it.

Light up on it, let it heat cycle. About heat cycle number 3 let it start to puddle nice tight arc. Here's where things get real. Slam the pedal to the floor and simultaneously bury your tungsten in the bit. Immediately let off. Even if this doesn't work trust me you will find satisfaction. It just feels so right.

Loosen the collet body leaving the tungsten behind. Let things cool off and pull her out.

It's taken years of practice, lots of tungsten, trust me you too can do it!

I like to call this hail mary, sink or swim.

Oil to water heat exchanger.

Got a chance to weld on these 3/4 s.s tube ends to this carbon head plate. It was so dirty oil keep coming out, after stoping oil and Welding I found every time I would weld on a thin spot the weld would pop,

Pretty frustrating, I used the CK machine with a pluse tig feature it helped a lot but, in the end it was the tube expander that did the trick.

I like beads like I like my women Hot 🔥 and heavy 😂💪 Stitch welding Dual shield flux core .045 I think I was running 24 volts 250 material thickness of out side plate 1/4" and 5/16" my welds were attaching the outside plate to the support frame. They had me weld it with all the supports in the way. Weird positions in the inside. Really difficult. I don't have thatuch experience with dual shield. More experience with hard wire. Some said my bead size was too big only supposed to be a 1/4. But better more than less. Not allowed to do multiple passes

Just finished the plate rack I was asked to build.

The steel came from left over drops I saved and, an old hammock stand I built a long time ago but never really used.

2x2x 1/8 tube 15' approximately

2" boiler tube .

12 x12 x 1x8 plate

2 hrs a day round up to 8 hrs

Used the CK to pluse tig weld the ends on the boiler tube (mainly to get familiar with the machine and its settings)

The square tubes were welded with a suit case powered by gas driven welder. (GMAW) Dailing in the wfs can be tricky but I got it.

22v 300 wfs/ volts were higher than the recommended 18 to 19 but, I set higher to make up for the voltage drop.

This was a gift but it's always good to know what I could or should charge.

Any feed back or constructive criticism accepted er I 🤔

Binge watching JD & Matt Hayden dual shield flux core videos pays off $$$. Thanks welding a bridge that goes over a tank for a mine. Probably copper mine. Dual shield flux core