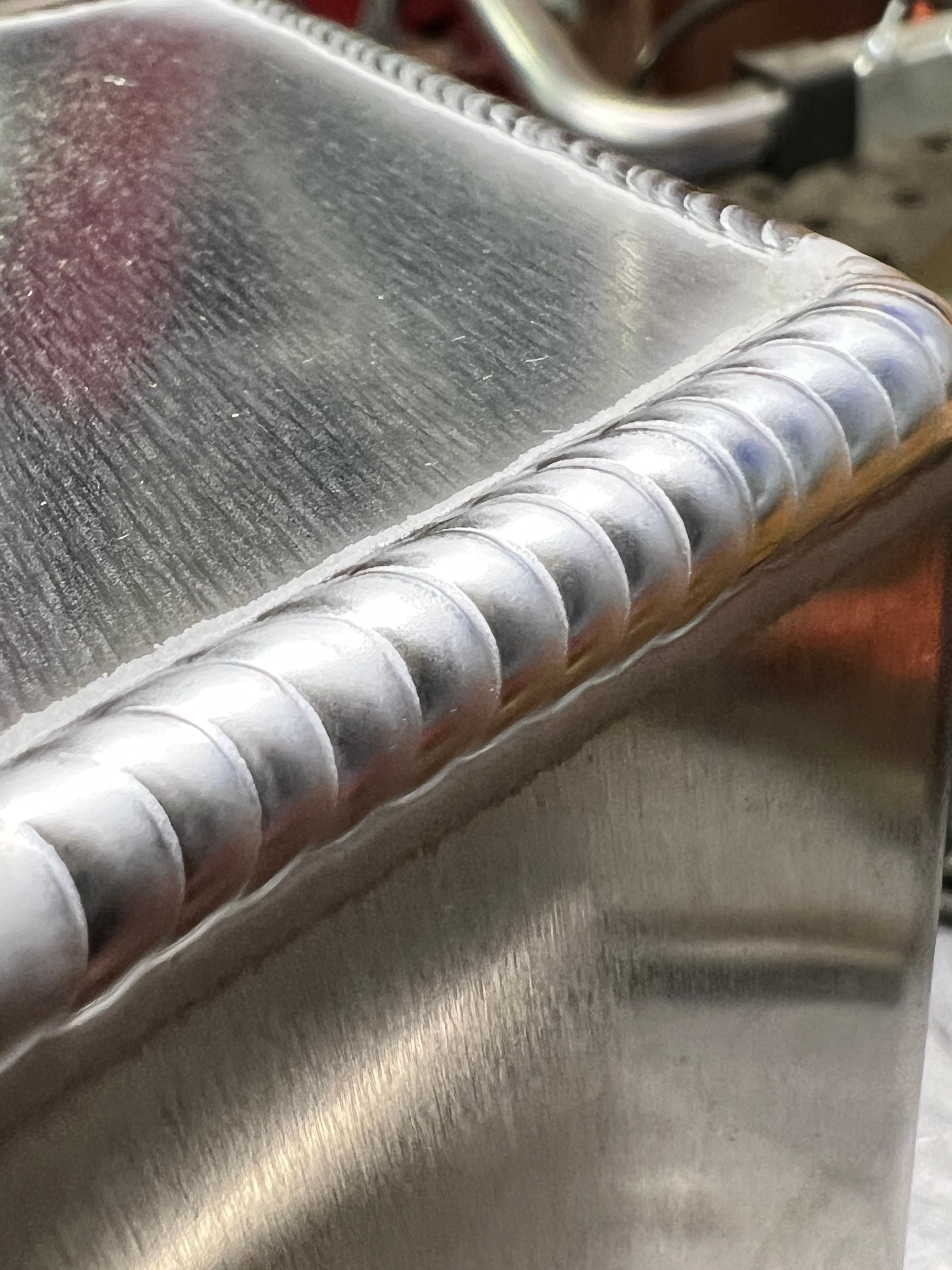

So here’s where we are Weld wise on Aluminum so far. Gonna be a cool video.

Brad Goodman

Posted

Posted

Commented on Hi all,Tonight I was given the opport...

Replied on Unboxing the new Primeweld 325 this m...

Replied on Hi everyone, My name is Kyle, I’m fro...

Replied on Any constructive criticism on these b...

Posted

Commented on Hi everyone, My name is Kyle, I’m fro...

Posted

Commented on So here’s where we are Weld wise on A...

24 Apr 17:31

Haha. Thank you bud.