Matt Hayden

JD Brewer

Hey guys, I need some Dual Sheild help.

Dual Sheild Flux Core, Lincoln ultra core .045 71T

-22v @ 240in/min 75/25 @ 45cfh- 3/16 square tube

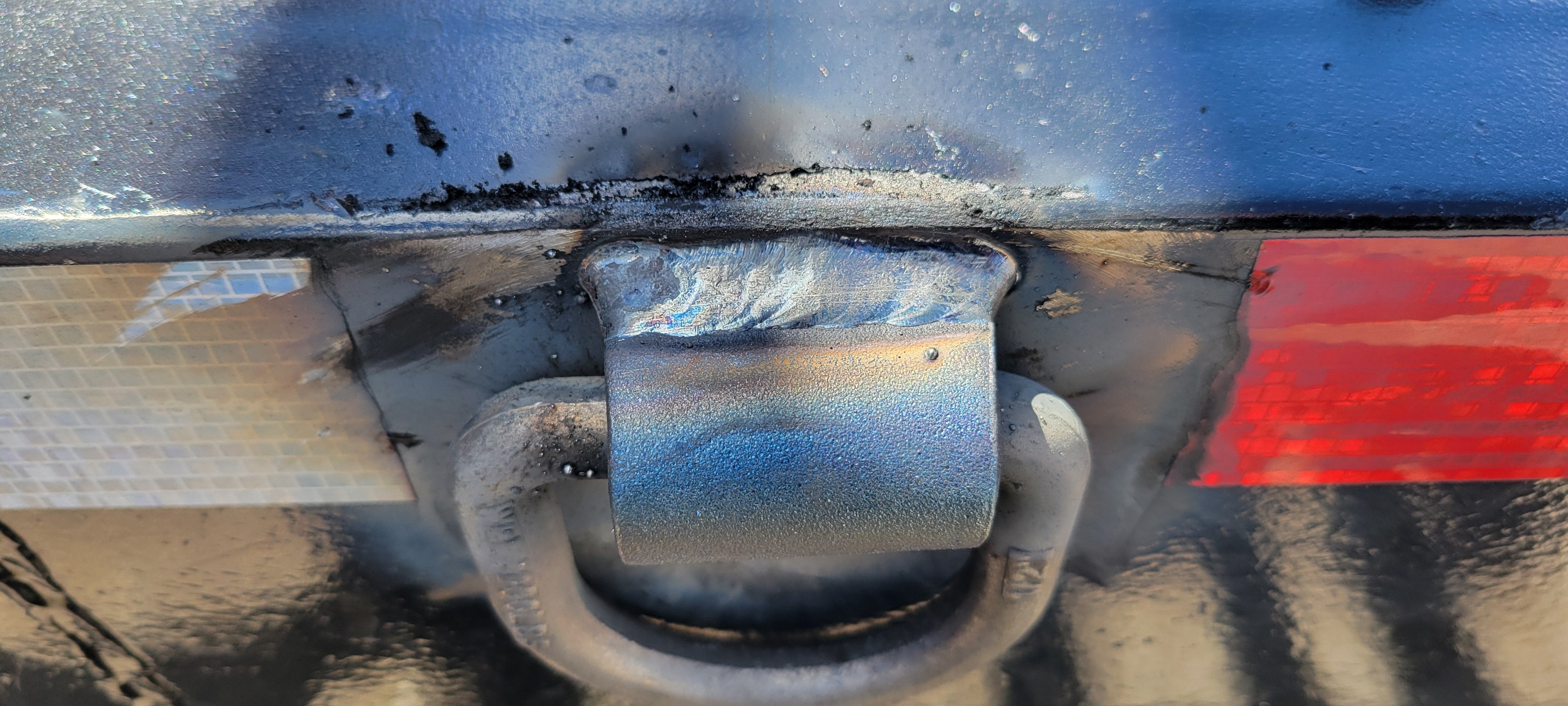

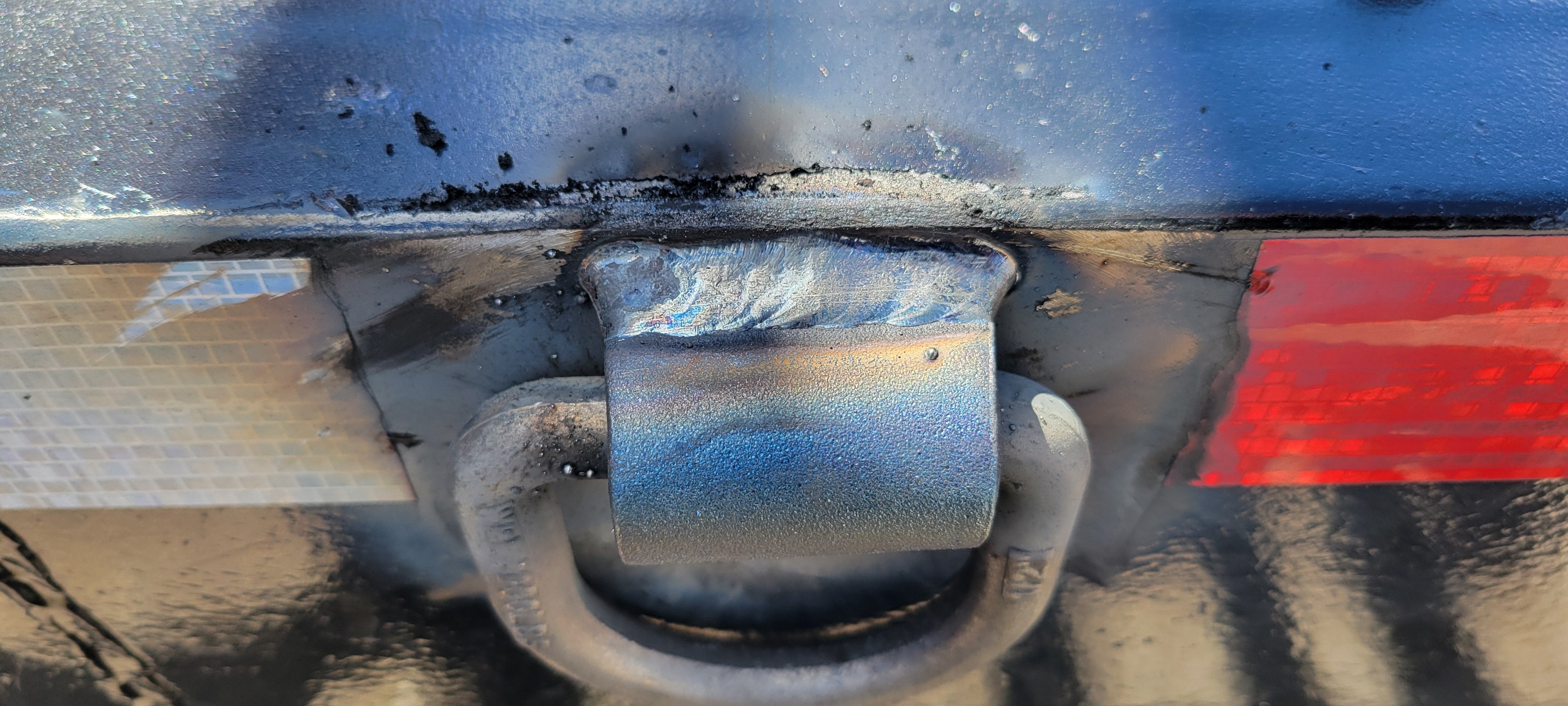

-25v @ 250 in/min 75/25 @ 45 cfh- 1/4- 5/16" D ring tabs

If I have a problem with the weld falling out, large balls of weld, would that generally indicate running too cold? Not enough arc force. I tend to weld alot of D Rings. The top weld goes in perfect, the bottom 4f t joint I always have problems.

I appreciate any advice

another new one from JD!

JD Brewer - Pipe Stub

Shop Sockets with JD!

JD Brewer - Shop Sockets

Hi everyone,

My name is Kyle, I’m from Melbourne, Australia.

I’ve recently learning aluminium tig, I’m about a week in and I can’t get enough!

Loving all the content on this site!

I have a question on weld penetration for aluminium.

I’m just wondering if there is different “ideal” penetration welds for different applications?

-Such as something you want to be as strong as possible, obviously requires full penetration.

-where as something maybe not so structural, example: Brad’s dog feeder boxes maybe you would want less penetration to have a clean finish on the inside?

I’m not sure if I’m on the right track here, maybe once you are good enough, a full penetration weld is just the norm and second nature.

If this is the case, it would be cool to see different examples of levels of penetration and the best way to go about achieving that particular finish.

(On all of the main metals, not just aluminium)

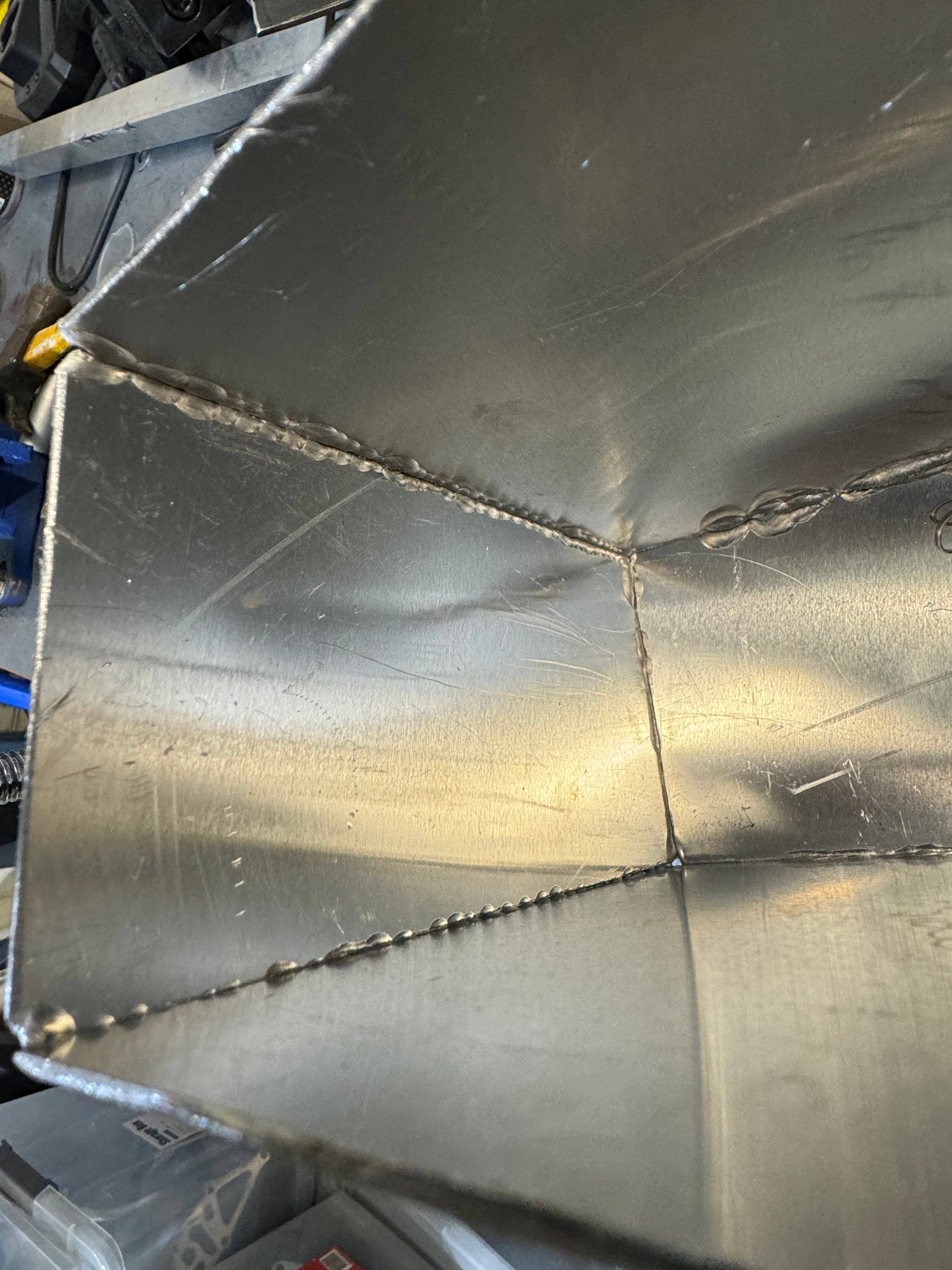

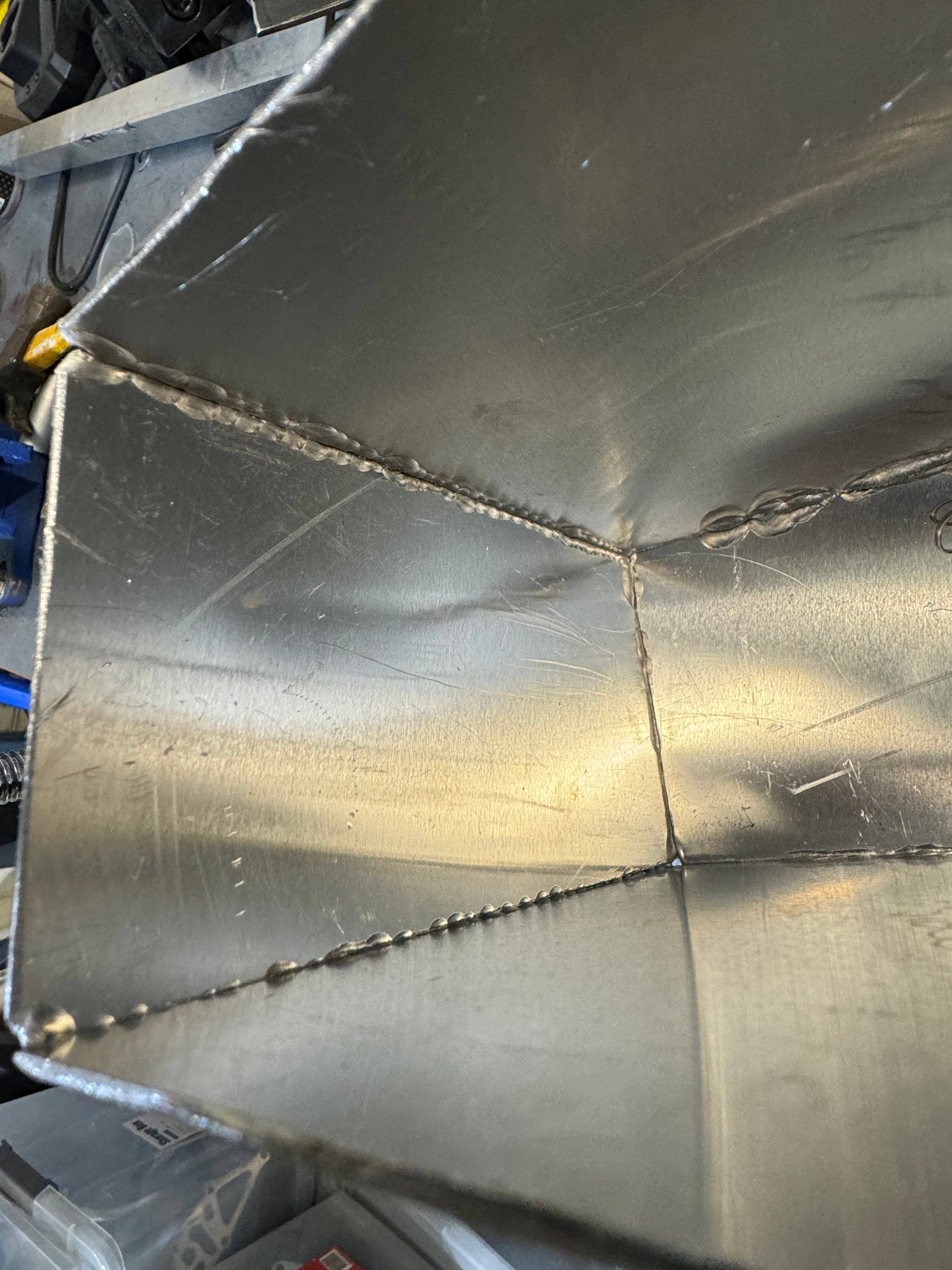

I have an example of some of my practice - I’m still learning to feed rod, that’s definitely my limiting factor. Sometimes I can’t keep up with the weld and I panic then it doesn’t go so great.

I am padding beads to get it up to speed.

I’m just wondering also if this penetration is what you would expect on an outside corner weld?

2mm Aluminium sheet - outside corner

~120 amps (140 amps on machine, foot pedal)

120hz, 30% cleaning, 17 torch, gas lens + 6 cup, 15cfh, 2% lanth 2.4mm tungsten

1.6mm filler rod - I found that 2.4mm filler was making my bead too high and cold looking.

Again, loving all the content on here! And really appreciate all instructors taking the time to teach us their tricks!

Cheers

A few new ones with Matt and Jody posted on the front page! Also, I found some videos that were bugged from when we migrated and made a little playlist for them. good stuff you may have missed if you signed on with us after we moved platforms. Check it out https://welderskills.com/categories/category-KyMBKqyRYlw

Has anyone used a brand of Dual Shield (FCAW) Electrode call "Diamond Spark" I heard a sales man came to the shop and had an employee test it. Salesman said that you did not have to chip off the slag because it would rise to the top after each pass over. No slag inclusion. It was cheaper than the Lincoln electrode and rated for structural AWS D 1.8 I did research and it is a German company.

Part 1 of a new series from Jody and Matt

2F LAP JOINT PULSE SPRAY MI...

Would it be possible for you to put together a video on what a tig weld should look like? I guess the criteria will be different for different materials, but things like the height, width, and the profile of the weld, color, sheen, start and end of weld, heat affected zone size, types of defects that we should look out for and how to fix them. I know that you guys are making great welds, but what things exactly should we be looking out for when we judge our tig welds? Thanks