I wanted to share a very advanced technique I have been working on since I started tig welding.

Not everyone can do it, takes alot of focus to perfect.

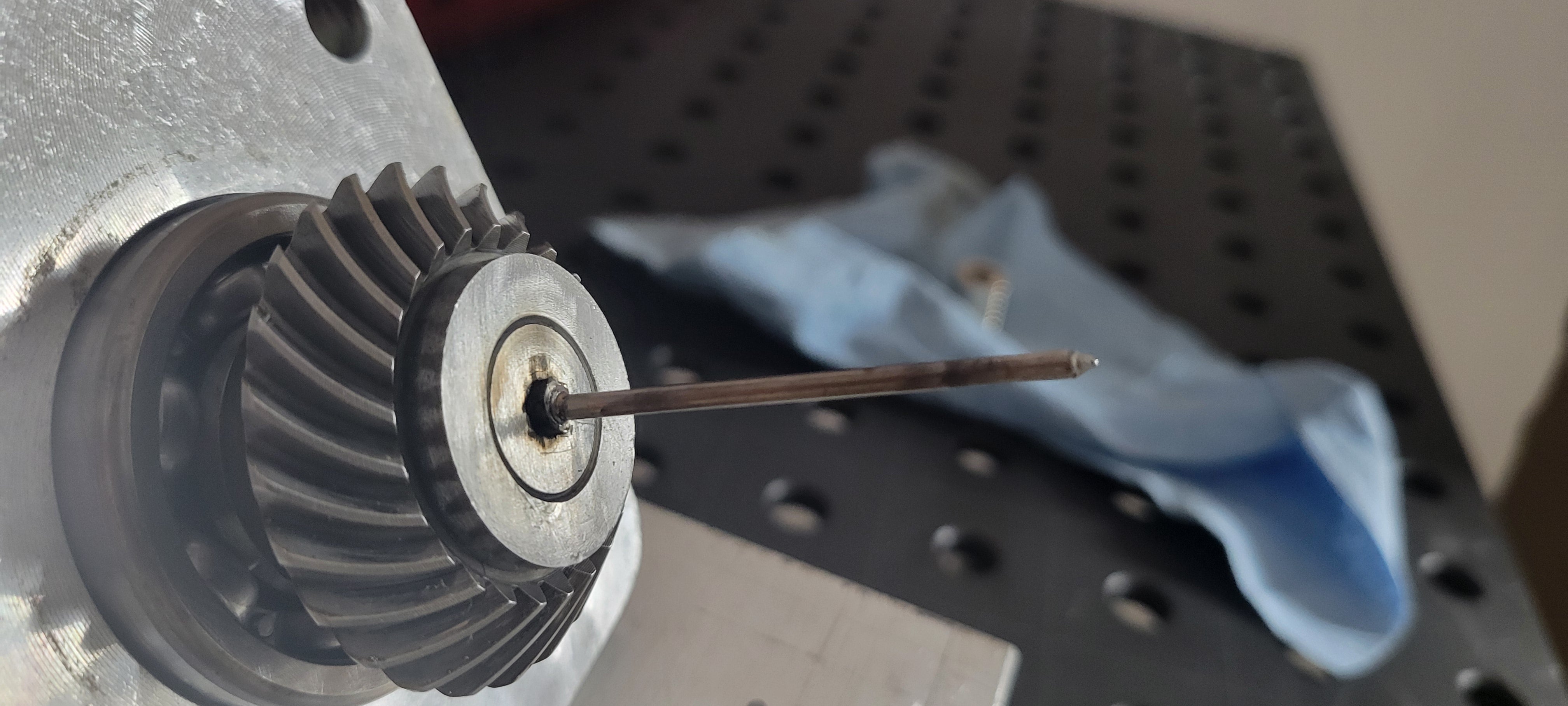

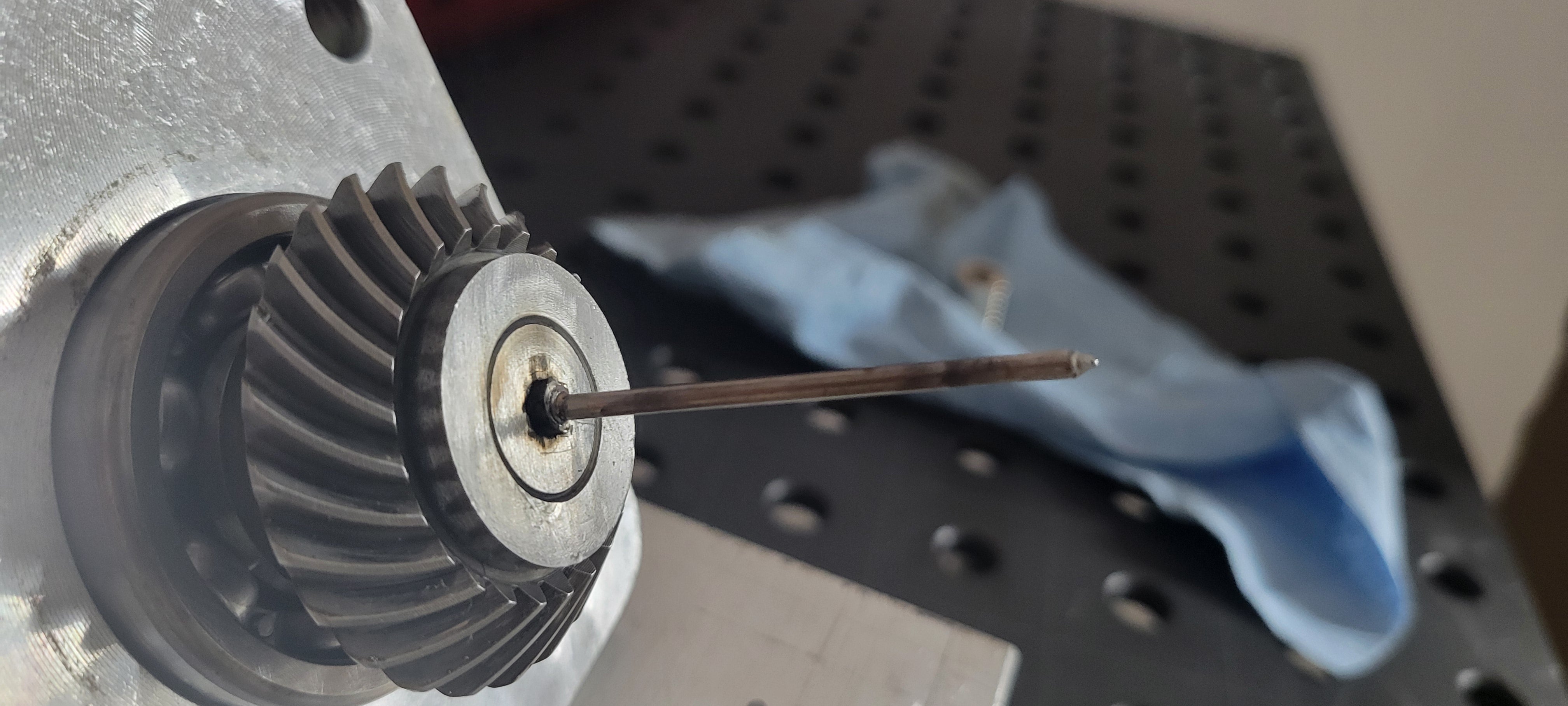

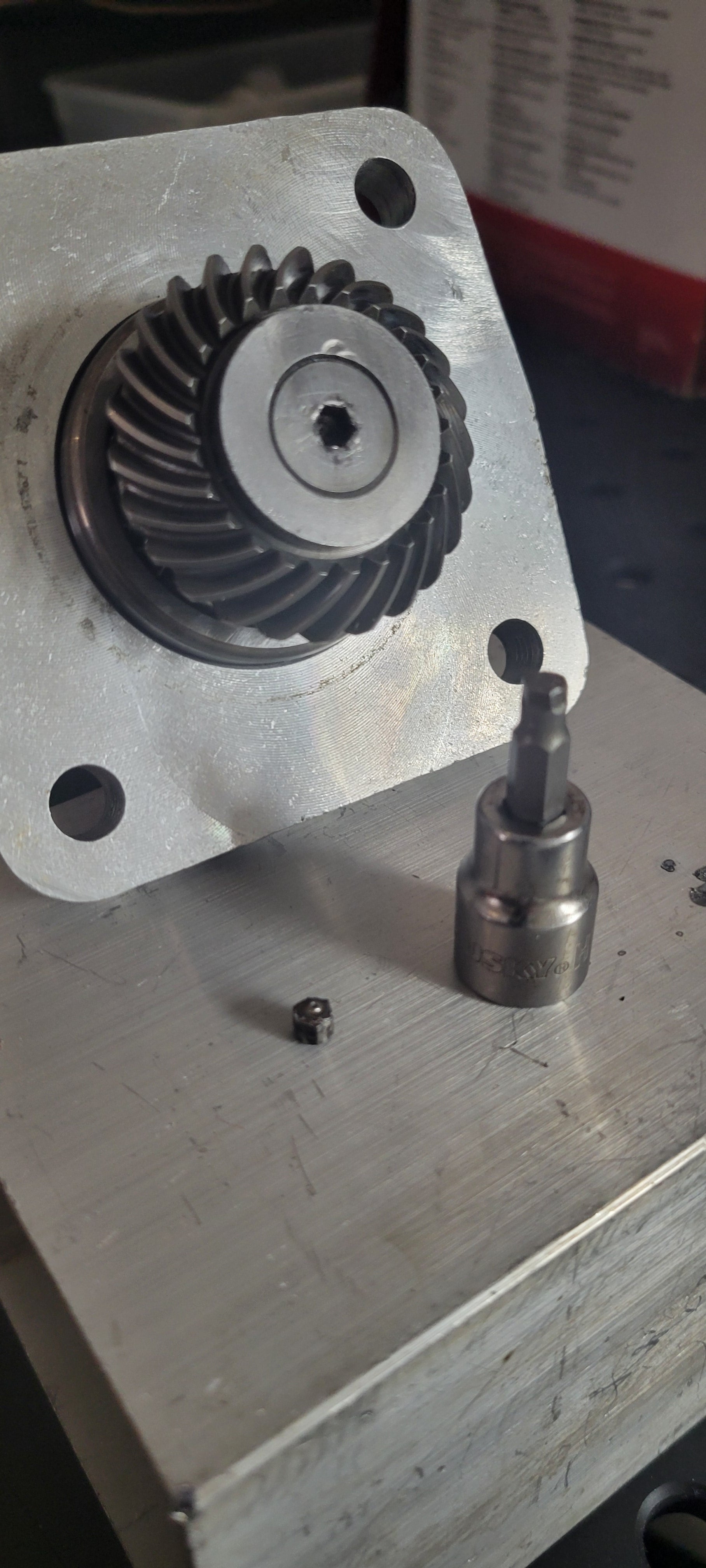

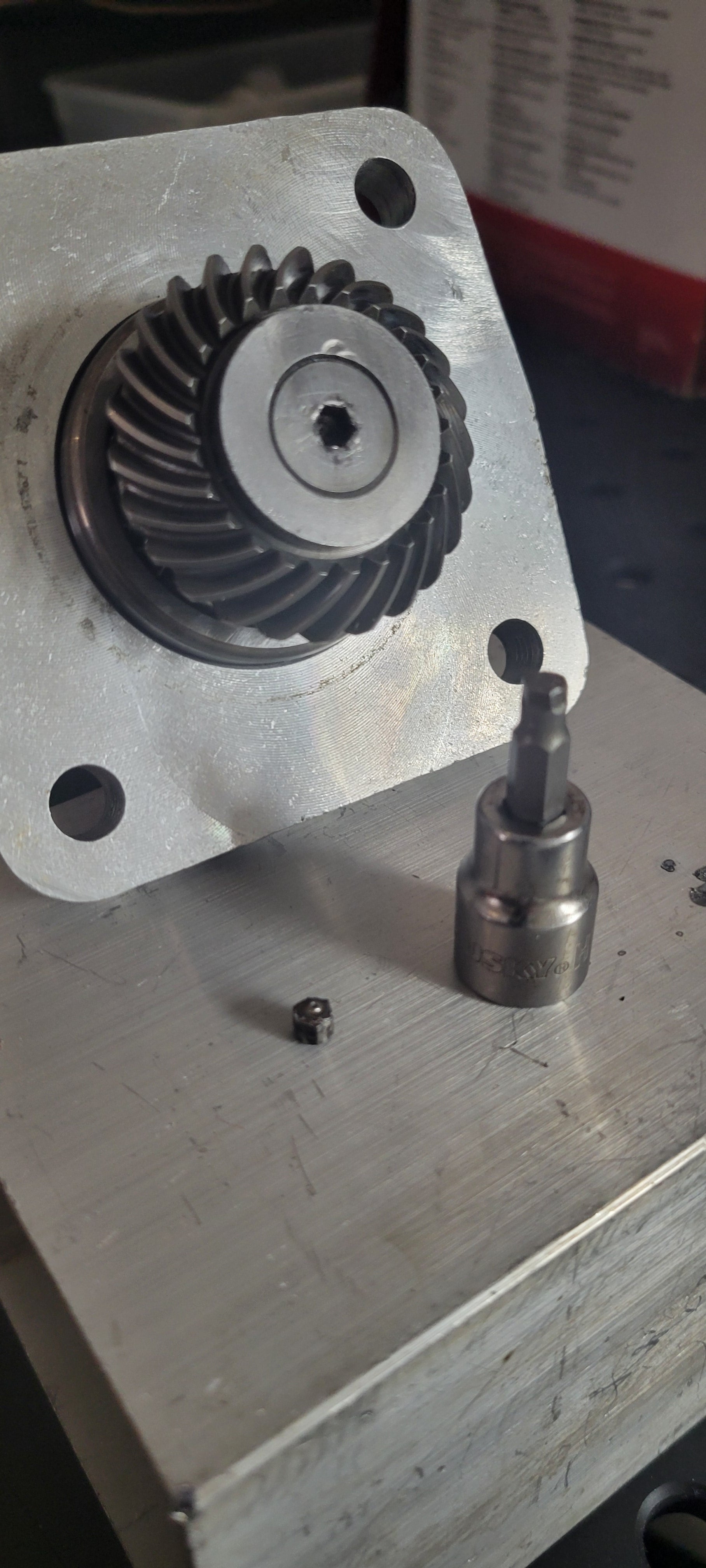

I was working on a $1500 Gearbox and snapped a hex bit off flush in a fastener. Rather than scrap it.

Light up on it, let it heat cycle. About heat cycle number 3 let it start to puddle nice tight arc. Here's where things get real. Slam the pedal to the floor and simultaneously bury your tungsten in the bit. Immediately let off. Even if this doesn't work trust me you will find satisfaction. It just feels so right.

Loosen the collet body leaving the tungsten behind. Let things cool off and pull her out.

It's taken years of practice, lots of tungsten, trust me you too can do it!

I like to call this hail mary, sink or swim.

New video from Matt Hayden on "DIG"

Matt Hayden - Arc Force Set...

new video from Sam on doing something quickly without cutting any corners

Sam Hagan - How Fast Can Yo...

Oil to water heat exchanger.

Got a chance to weld on these 3/4 s.s tube ends to this carbon head plate. It was so dirty oil keep coming out, after stoping oil and Welding I found every time I would weld on a thin spot the weld would pop,

Pretty frustrating, I used the CK machine with a pluse tig feature it helped a lot but, in the end it was the tube expander that did the trick.

Finaly made the core suport and layed my intercooler pipes and was able to do it just thinking I may try and make the pipes with less boots

New video from Jody. Jody will be going live Wednesday with Brad to talk about working with unfamiliar materials!

Down & Dirty Tip for TIG We...

Another new one from Jody to kick the week off!

4140 Build up Beads and Hig...

Really big plasma table can cut 1 inch thick plates. At my job.