Thank you Michael. Enjoyed the conversation.

Brad Goodman

Commented on WS Podcast - Jody and Brad | "TIG Aluminum Prep"

Posted

Commented on Finally got the stickers! I’ll put up...

Replied on If you wanna watch me dial in the Pri...

Commented on 3/32" 7018 Tube to Plate Multipass Fillet

Commented on If you wanna watch me dial in the Pri...

Commented on So here’s where we are Weld wise on A...

Posted

Replied on WS Podcast - Jody and Brad | "TIG Aluminum Prep"

May 16 at 06:02 PM

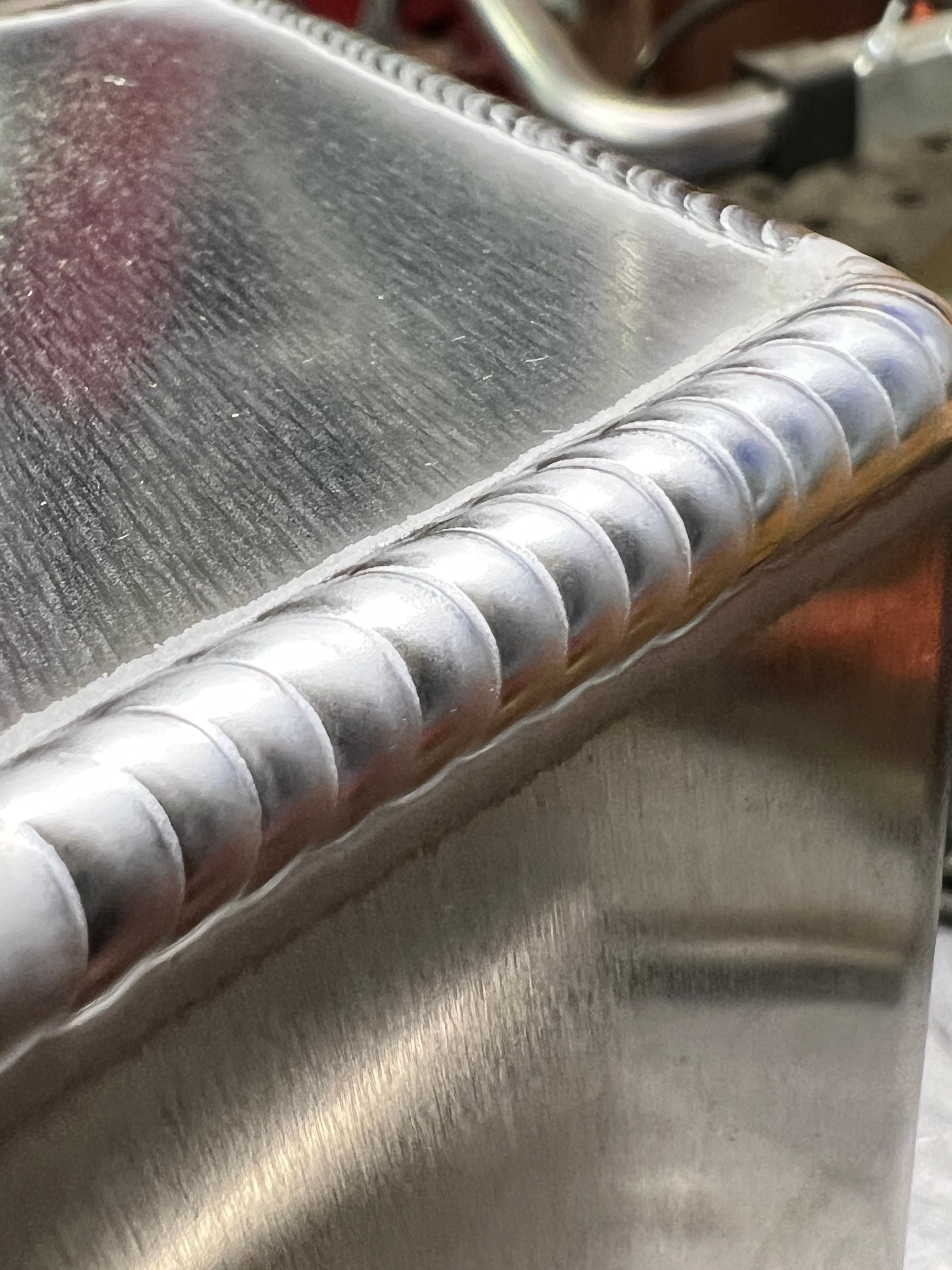

That’s exactly what that greying is. Hot tungsten attracts it and it sticks. Sometimes a simple buffing with scotchbrite and or fine sandpaper will do the trick as long as you take it back to good shiny tungsten. I always light up on a scrap piece before I start with a newly prepped tungsten to burn off any of the impurities caused by the grinding or polishing.